M. Reukaufii, a Nectar-inhabiting Wild Yeast with Biotransformation Potential in Hoppy Beer

Nectar specialist yeast like M. Reukaufii has been found to alter the composition of nectar to create fruity compounds to potentially increase the chances of pollination, can it amplify fruity notes in beer too?

I

t’s great when the science and study from one research area gets applied and tested in a completely different realm. In this case, on the backs of researchers examining nectar inhabiting yeasts for pollination purposes, brewers are using their results to experiment with some of the same yeasts in an attempt to maximize and compliment hoppy fruit aromatics.

In this post, I do my best to navigate some of the academic work done on nectar specialist yeasts and their impact on nectar composition and, ultimately, pollinator attraction. I reach out to one of the leading authors in this field for a little help in understanding their excellent work. I then finally brew a few test batches with one of the more common nectar yeasts (M. reukaufii) and discuss the results and recipes and discuss biotransformation potential with commercial enzymes.

What are Nectar-inhabiting Yeasts?

In simple terms, flowers contain nectar, which is a sugary liquid produced by the plant, which attracts pollinators. Naturally occurring in some of the nectar (or transported by pollinators) are what’s called Nectar Inhabiting Yeasts (NIY). These floral nectar yeasts and bacteria produce volatile compounds that can impact their floral visitors. For example, one paper found that the yeast in pollen produced volatile signals that may attract pollinators. 2

The “fermentation” done by nectar yeasts may help attract pollinators for many reasons, like warming the nectar, altering the sugars and amino acids, altering the nectar’s scent, and influencing the acidity (similar in some ways to how beer fermentation changes wort). 1 Of the nectar-inhabiting yeasts studied, Metschnikowia reukaufii (M. reukaufii) is one of the most common. Bumblebees have been found to favor flowers colonized by M. reukaufii as well as spent more time on the flowers compared to yeast-free flowers. 1 1

So what compounds are nectar inhabiting yeast like M. reukaufii creating in pollen that is attracting pollinators? Below is a chart of compounds tested in nectar 1 that may be relevant when we are thinking about using the strain in the production of beer.

| Category | Compound | Description |

| Aldehyde | Acetaldehyde | green apple |

| Alcohol | 3-Methyl-1-butanol | banana, pear |

| Alcohol | 2-Pheny ethanol | floral |

| Ester | ethyl acetate | fruity, pineapple |

Of course, the makeup of wort and nectar are entirely different, but I still find it interesting to see what compounds M. Reukaufii creates when fermenting glucose and fructose in nectar for potentially understanding and applying it in beer. It seems likely to me that (like most things in beer), it’s a complex set of esters and alcohols along with the potential biotransformation abilities of M. reukaufii that might contribute to its flavors when paired with other yeasts and hop compounds.

Biotransformation and Fermentation Potential of M. Reukaufii

I’m so far from an expert on any of this, so I reached out to Rachel L. Vannette, Ph.D. Assistant Professor Department of Entomology and Nematology University of California, Davis, who authored one of the papers looking at the different compounds created in NIY for some clarification and guidance on the topic of biotransformation capability of M. reukaufii. Vannette directed me to the recent work of some of her collaborators who sequenced the genome of R. reukaufii (MR1). She sent me to a site that shows active enzymes among a genome (in this case, MR1). Some of these enzymes do look functionally similar to beta-glucosidase as part of the Glycoside Hydrolase family.

I like to think about releasing bound hop-derived compounds into two groups to keep things straight in my head. The first is the potential to free bound thiols, and the other the release of bound glycosides. Both pathways need separate enzymes to achieve biotransformation. This concept is similar to your mash, where alpha and beta-amylase enzymes are required to break starch down into fermentable sugars.

Enzymes needed for releasing bound hop compounds:

Bound hop-derived thiol release – β-lyase (3MH, 4MMP)

Bound hop-derived glycoside release – β-glucosidase (monoterpene alcohols like geraniol, linalool)

M. reukaufii has the MR1 gene, which is cited as having an active enzyme capable of releasing bound glycosides, not thiols. So what does this mean? If a hop has been found to have high amounts of bound geraniol and is used in the whirlpool and then fermented with an enzyme active yeast (like M. reukaufii), it’s possible to benefit from both the free geraniol as well as releasing additional geraniol from the hop. The release of bound geraniol could be even more important when you remember that geraniol is known to be bioconverted to β-citronellol during fermentation, with ale strains means going from more herbal-like geraniol to a more citrus-like β-citronellol. The more geraniol released into the wort (both free and bound) the more potential for this bioconversion!

Although the release of some of these bound monoterpene alcohols might not make a beer completely explode in fruit flavors, as was found in one study 1 it does seem that enhancing the concentrations of some of these desirable compounds could at the very least add to the complexity of your beer and potentially increase synergy among other compounds.

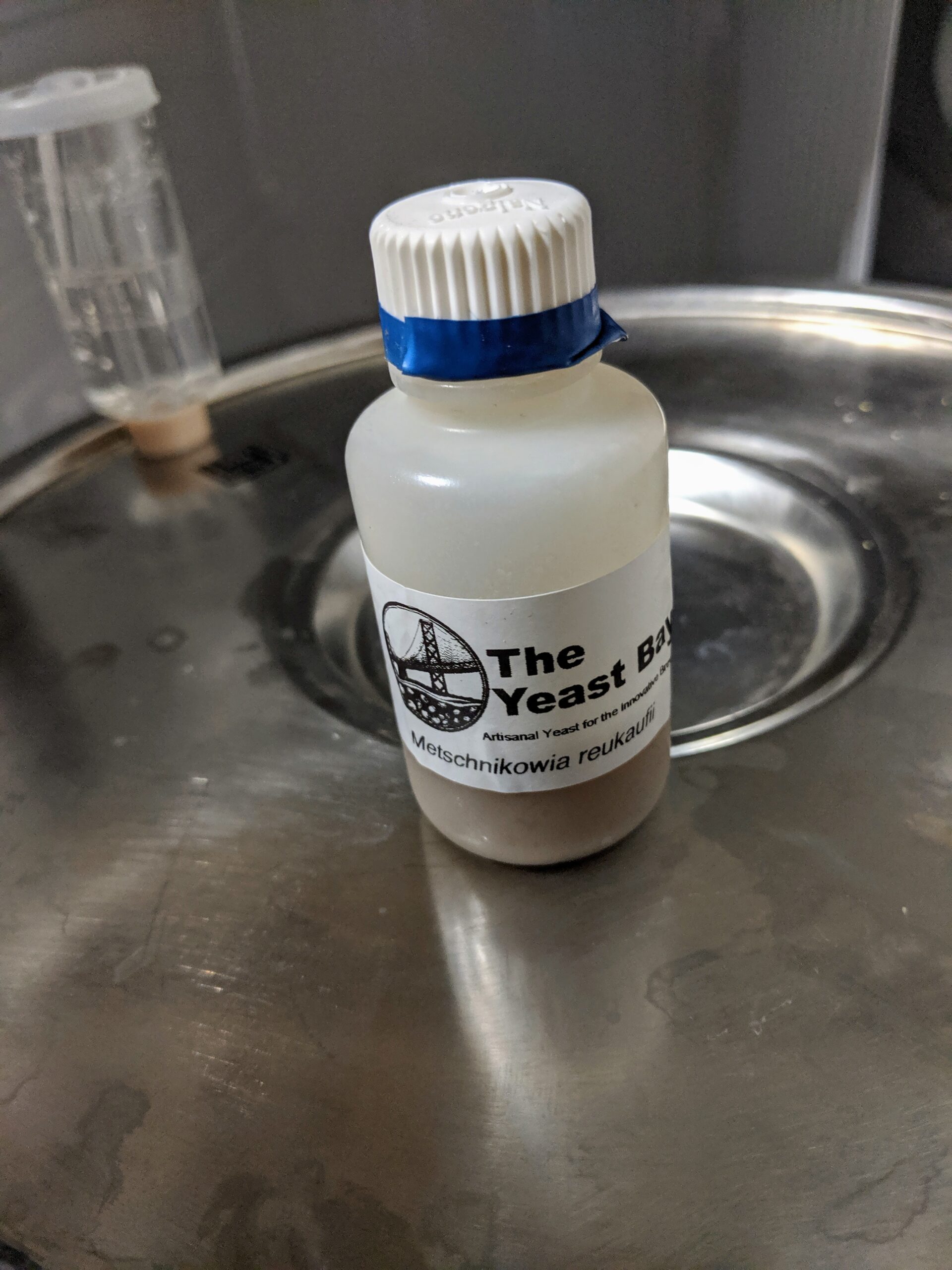

So, getting back to nectar and pollinators, The Yeast Bay has isolated M. reukaufii and now sells it to be used to ferment in beer. The idea is that this nectar specialist yeast can help bump the sweet fruit aromatic characteristics of beer to attract bearded men similar to how NIY attracts pollinators in flowers (sorry, had to). As the Yeast Bay site suggests, the bumping of flavors from M. reukaufii could be by “enzymatically altering otherwise inodorous nectar compounds like glycosides,” which we now can see may be from enzyme activity found in the MR1 gene.

The Yeast Bay suggests that to use the nectar yeast, its best to co-ferment it with another brewing strain because it can only attenuate 20-25% in brewers wort because it doesn’t utilize maltose (the primary sugar source in wort). In my little experience with M. reukaufii, I would suggest experimenting with co-pitching with a healthy saccharomyces strain. Although, it would be interesting to add glucoamylase to the mash to convert all the starch/maltose into glucose and then perform the fermentation with only M. reukaufii to see how it performs. My first small batch experiment resulted in obvious acetaldehyde (which the chart above did find in nectar ferments). Perhaps the London Ale III strain I pitched with it wasn’t healthy or strong enough to clear up the acetaldehyde produced by M. reukaufii?

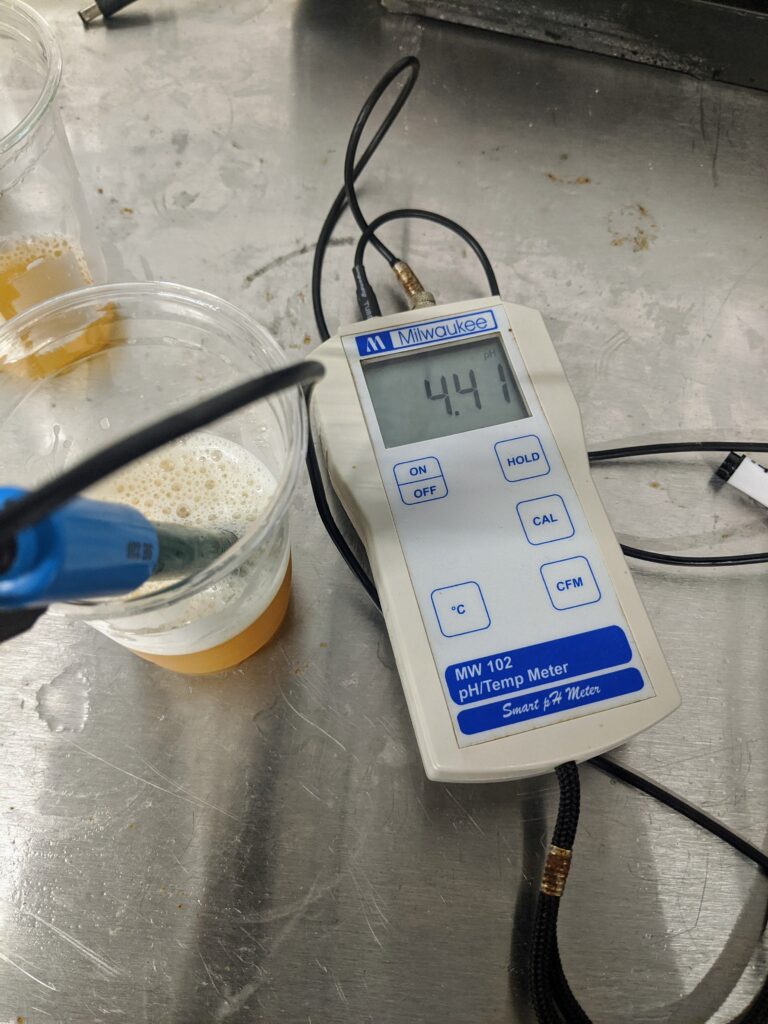

One of the other potential benefits The Yeast Bay suggests may come from fermenting with M. reukaufii is the softening of the the perceived bitterness of beer. I speculate if this might have something to do with the strains ability to quickly drop the pH of fermenting wort. In studies looking at the perceived bitterness perception in hoppy beers, it was determined that the higher the pH of beer, the higher the perceived bitterness, which is why I’m interested in potentially adjusting the final pH of hoppy beers to see how it can impact drinkability. As it relates to one of the experimental batches I did with M. reukaufii and Saccharomyces “bruxellensis” Trois, after a dry-hopping at a moderate rate of 8.5 ounces in 5-gallons (240 grams in 19-liters) the final pH of the beer was 4.41. This reading is a little lower than I’m used to seeing at those dry-hopping rates (we typically see final pH readings in heavily dry-hopped beers of 3 pounds per bbl+ (~12 grams/liter) in the range of 4.5+).

More tests would need to be done to see if M. reukaufii is a reliable pH dropper, but I wonder if that might play a beneficial role in heavy dry-hopped beers like DIPAs along with its flavor-boosting potential. It’s been my experience that slightly lowering the pH in some higher ABV and heavily dry-hopped beers make them a little more approachable on the palate.

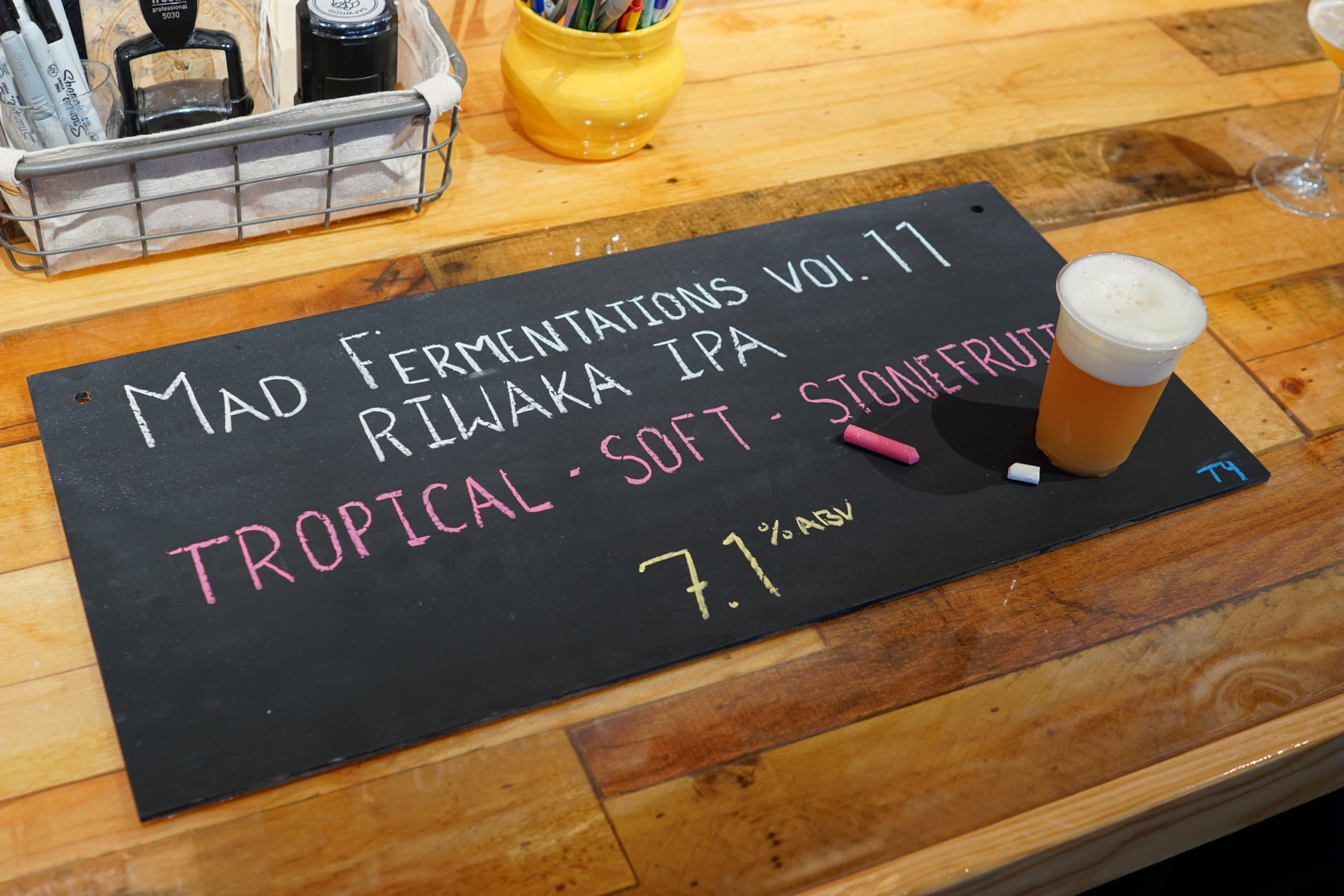

Both of these experimental batches utilized a relatively new hop called Riwaka. I’ve been a fan of Riwaka since having a single-hopped Riwaka pale ale from Hill Farmstead Brewery. Unique from most of the other varieties regularly used in hop-forward beers, I find it can have a fruity candied-grape character with a little spiciness (which can come across as diesely to some). Riwaka is also a variety (granted, I’ve only used it a handful of times) that seems to have strong staying power when used as late whirlpool addition. The staying power was especially true in an IPL we brewed and fermented cool with Tum 35. Perhaps the lower fermentation temperature, combined with the lower whirlpool temperature, helped retain more of Riwaka’s volatile compounds.

Riwaka has been a problematic hop to acquire (especially for commercial brewers), but as my luck would have it, Kemsley Eggers of Egger’s Hop Growers reach out to me after reading the New IPA. After chatting with Kem on the phone about his farm in New Zeland, the challenges and perks of running a hop farm, and of course, a little hop science, Kem asked if Sapwood would be interested in brewing with some of his Riwaka. It’s a fun experience to interact directly with the farmer, especially one so interested in what brewers think of his years of hard work. Hopefully, we can keep the dialogue going with future crops and different varietals!

Let’s get to some trials using M. reukaufii in hoppy beers! First, I’ll walk through a small batch experiment co-pitching M. reukaufii with Saccharomyces “bruxellensis” Trois. I’ll then give the recipe and results of a much larger commercial-scale batch with the M. reukaufii in collaboration with a local brewery.

M. reukaufii, and Saccharomyces “bruxellensis” Trois Recipe

Brewed: October 2020

Tasting notes: October 2020

Batch size: 5.5-gallon

| OG/FG/ABV | Est. IBU | SRM | Water | Mash Temp. |

|---|---|---|---|---|

| 1.072/1.019/7.1% | 55 | 5.0 | ~150 ppm chloride and 100 ppm sulfate |

152°F

|

| Grain | Percentage |

| Pilsner | 70% |

| Red Wheat Malt | 24% |

| BEST Chit Malt | 6% |

| Hot-Side Hops | Amount | Timing |

| Wakatu | 30 Grams | Mash Hop |

| Wakatu | 110 Grams | Whirlpool 180°F (82°C) |

| Riwaka | 170 Grams | Whirlpool 180°F (82°C) |

| Yeast | Amount | Duration |

| Saccharomyces “Bruxellensis” WLP644 | 45 Grams (new homebrew pack) | Pitched at 62°F(16°C) and set controller to 72° (22°C) |

| Metschnikowia reukaufii (WLP4650 | 20 Grams | Pitched at 62°F(16°C) and set controller to 72° (22°C) |

| Dry-Hops | Amount | Timing |

| Riwaka (2020) | 100 Grams | At Yeat Pitch |

| Riwaka (2020) | 140 Grams | Post-fermentation in a purged keg at 60°F (15°C) |

Result

Four days after the start of fermentation, I took a quick sample and was already pleasantly surprised (of course, it was already dry-hopped with a modest charge of Riwaka). Already down to 1.024, I thought the beer smelled its best at this point. I got a big fruity note from it in a tangy grape way. I’m guessing that tangy brite note might be coming more from the small amount of M. reukaufii paired with the pineapple-like esters that can come with Sac Trois, but it’s hard to say for sure. There was a hint of the spice/diesel thing you can get from Riwaka, but it was the mildest at this stage compared to post-fermentation dry-hopping.

The beer ended up dropping a few more points before I dry-hopped it again with Riwaka in a purged keg. I left the keg at room temperature for 5 hours before going into a cold room at 40°F (4°C) for a few days. Although I make a case for cool dry-hopping, it does seem that when the temperature is less than 50°F, it takes more agitation to get good extraction. I theorize that the cooler temperature encourages hops to drop to the keg’s bottom faster at these temperatures. After a number of these smaller batch experiments at the brewery (dry-hopping in the cold room), I’ve noticed that I expected more of an aromatic punch based on the dry-hopping rates used in these beers. Because of this, I’ve been keeping the keg at 10-15 PSI and swirling the keg multiple times throughout the day to try and get those hops back in the beer.

After post-fermentation dry-hopping and carbonation, I was pleased with how the beer turned out but it could benefit from some tweaks. I still need to experiment more with Riwaka, but I think I might enjoy the flavor I get from it in the whirlpool and active fermentation dry-hopping. I don’t think of active fermentation dry-hopping so much as biotransformation hopping but more to alter a variety’s perception in the final beer, and Riwaka might be a good example of this approach. I preferred the dry-hop character from the early dry-hop addition compared to the post-fermentation flavor. To me, the active fermentation helped to push out some of the hop’s rough edges (spicy flavors), seemingly leaving behind more of the fruit-forward compounds. My guess without getting the beer tested for compounds is that the more volatile and woody/spicy hydrocarbons are being actively scrubbed, and the more soluble monoterpene alcohols are staying behind.

If I did this beer again, I’d probably take the advice of my beer palate coach Spencer Love, and pair the early addition Riwaka with a more fruit-forward tropical hop to bring out what I like about Riwaka even more. It seems like doubling down on it post-fermentation helped exaggerate what I don’t necessarily like from the hop. I think the same would happen when pairing it with another dank, spicy, and sweaty varieties like Nelson Sauvin (I’d understand how others might actually like this flavor, however). Citra or Galaxy might be great choices to pair with a beer like this rather than the post-fermentation Riwaka addition.

Sapwood Jailbreak Collaboration

One of my good friends going back to DC Homebrewer meetings is Rob Fink, who is now the Lead Brewer at Jailbreak Brewing Company in Laurel, MD. Unlike most homebrewers that moved to brew commercially, Rob still finds and enjoys homebrewing. After spending a week milling thousands of pounds of grain, cleaning out mash tuns, running CIPs, you can see how a weekend without stainless might be appealing. However, similar to my experience brewing commercially, he finds the smaller batch experiments are where he can scratch his creative itch.

After I posted an article on some of the latest research on “survivables” and hot-side hop flavor, Rob sent me a text late that night after reading it saying, “I have determined that we should collab on another hoppy beer ASAP.” Our goal, to throw a lot of bioconversion-related science at one beer and see what might stick!

The beer, ultimately named Sisyphean Task, was eventually brewed and canned at Jailbreak’s facility. We decided to get some supporting bitterness with Warrior extract; when an IPA is as big as 9%, it needs a little balancing bitterness, in my opinion. We then layered in hot-side hops that new science suggests are better at providing hop-saturated survivable flavor. Mosaic and Idaho 7 were added to the whirlpool after cooling, and then we added a 3MH-rich hop in Columbus to the fermenter at yeast pitch. To boost hop thiol potential, we added Scott Lab’s Revelation Aroma, a β-glycosidase active enzyme, to potentially release bound hop glycosides. In addition, we added Scott Lab’s Revelation Rapidase Expression Aroma, which can potentially release bound hop thiol compounds. Both enzymes were added at yeast pitch with the Columbus Cryo® dry-hop. We also hoped that adding Columbus during active fermentation might help push out some of the more volatile hydrocarbon compounds that can lend more resinous, green, and spicy flavors and aromas (similar to what happeend to the Riwaka above).

To take the bioconversion goal one more step forward, we also co-pitched the beer with M. reukaufii for its flavor-enhancing ability (whether through ester production or enzymatic activity). Rob had been experimenting with M. reukaufii with some smaller batches in various contexts, but mainly in hoppy beers in an attempt to achieve its advertised potential of increase fermentation expression of hop-derived flavors. Mainly, Rob had co-fermented M. reukaufii with yeast strains such as Conan or Wyeast’s West Yorkshire, which alone can provide excellent stone fruit esters, but the amplification from M. reukafuii was something he was enjoying.

Rob has used M. reukaufii a half dozen times and finds that he notices its absence more than its presence. When co-fermenting with Conan, he can tell there is a higher level of yeast complexity and potentially more synergy among hop and fermentation compounds.

Of course, when you are doing so many different things at once, like using multiple hop varieties, experimenting with more than one enzyme, co-pitching yeast (especially one originating from nectar), it’s challenging to know what exactly is doing what in the final beer’s profile. Sometimes, it’s just fun to layer variables and processes inspired by the research and see what you get. This experimental to the max approach is kind of what makes collaborations so fun!

Sisyphean Task Recipe

Brewed: October 2020

Tasting Notes October 2020

Batch Size: 5.5 Gallons

| OG/FG/ABV | Water |

Mash Temperature

|

| 1.092/1.023/9% | Ca:135 ppm, Mg:5 ppm, Na:72 ppm, CI:246 ppm, SO4: 120 ppm | 158°F (70°C) |

| Grain | Percentage |

| Rahr 2-row Pale | 34% |

| Weyermann Pilsner | 29% |

| Weyermann Pale Wheat | 16% |

| Crisp Malted Naked Oats | 8% |

| Rahr Unmalted Wheat | 5% |

| Flaked Oats | 5% |

| Weyermann Acidulated | 3% |

| Hot-side Hops | Amount | Timing |

|

Warrior Resinate, 150 GMA (Bittering)

|

60 Minutes | |

| Idaho 7 Cryo Hops® | 40 Grams |

Whirlpool 180°F (82°C)

|

| Mosaic Cryo Hops® | 40 Grams |

Whirlpool 180°F (82°C)

|

| Dry-Hops | Amount | Timing |

| Columbus Cryo Hops® | 40 Grams |

Added at Yeast Pitch

|

| Riwaka | 125 Grams |

Post-Fermentation

|

| Strata | 125 Grams |

Post-Fermentation

|

| Citra Cryo Hops® | 80 Grams |

Post-Fermentation

|

| Yeast/Enzyme |

Temperature/Timing

|

| Imperial Juice |

Pitched at 68°F(20°C)

|

| Metschnikowia reukaufii WLP4650 20 Grams |

Pitched at 68°F(20°C)

|

| Rapidase Expression Aroma .35 grams | Yeast Pitch |

| Rapidase Revelation Aroma .35 grams | Yeast Pitch |

Result

I like to rib Rob occasionally for his expansive vocabulary and pontificating skills, especially when discussing beer (mainly because I don’t know what he is saying). But, I have to admit, it does make the beer sound incredible. Because of this, I’m going put word-for-word Rob’s description of the beer he sent in an email before canning day because it’s so great.

“Early into fermentation, the ester production was reminding me a lot of a hot kveik fermentation, where the esters can get excessively tropical, in a one-dimensional sense. As fermentation wore on, that character was modulated quite significantly, and it eventually became harmonious, multi-dimensional, and, to be honest, quite compelling.

The body is rich without appearing on the palate as excessive or sweet. A cornucopia of fruit character (with no fruit added), simultaneously tropical (overripe, musky passionfruit) and brightly citric (caracara orange, ruby red grapefruit),

Overall palate expression is a vivid portrait of hop character and the complexity of fermentation, the latter of which is derived from a combination of thiol-enriching enzymes, a nectar yeast cultivated from brambleberry bushes, and conventional English ale yeast. Grist mostly comprises malted wheat, flaked oats, and raw wheat establishes a soft, incredibly silky foundation for the dry-hop assault of Riwaka, Strata, and Citra cryo.”

Is it worth using commercial enzymes in an attempt to increase biotransformation potential?

It’s tricky to say; I’ve talked to some commercial breweries who do it and think they get a little more flavor-retention in their hoppy beers when they use it. Others don’t seem to think it’s doing much for them.

We can look at the results from a 2020 MBAA paper that tested whether using exogenous enzymes prepared for either hop-derived thiol or glycoside release impacted a hoppy beer. Using Galaxy and Enigma for the dry-hops, the enzyme-treated beers were put in front of a sensory panel, and the results were surprising. The glycoside releasing enzyme created a beer that was more herbal and resinous compared to the control beer. Similarly, the thiol releasing enzyme created a more resinous, berry, and vegetal (onion/garlic) beer compared to the control.2 Side note, the authors of this particular paper just happen to be great dudes and worked hard at translating my book into Spanish, which should be releasing soon!

So at least in the case of Galaxy and Enigma, the enzyme-treated beers certainly did impact the beer but made them lean a little more herbal and resinous rather than amplify the fruitiness. I tend to think that glycoside-freeing enzymes would have less impact on flavor than thiol releasing because of the low taste threshold of thiols. There will hopefully be more studies like this in the future. However, I think there is still potential for enzyme usage, especially with hops tested to have high amounts of bound thiols and monoterpene alcohols.

Lallemand has recently released an β-glucosidase enzyme called AROMAZYME specifically to be used in beer (most of the enzymes are directed at winemakers). They sent Sapwood a small sample of it for us to experiment with, and we put it to the test in a split batch experiment. I took ~16 gallons of wort from a 20 BBL tank the day after pitching the yeast and added AROMAZYME to the 16-gallons to see how it might impact the flavor from the hot-side hops (Amarillo and Mosaic). Both Mike and me were able to tell the difference between the beers. The beer that fermented with AROMAZYME was a little more complex, brighter, and punchier with a slight banana tropical thing to our palates. The beer that fermented without the enzyme was a little more “from the bag” hop character, which tends to be greener. It would be interesting to do this again, but to get the samples tested for actual compounds.

One potential reason our results differed from the MBAA study could lay in the different hop varieties used and the potential for enzymes based on their respective bound compound composition. For example, one study investigated glycosidically-bound flavor potential in beers made with the 42 hop varieties. Using a commercial β-glucosidase enzyme to release the monoterpene alcohols, researchers found that Amarillo® showed the most glycosidically-bound geraniol potential. Mosaic was also found to test high in bound geraniol (as were Bravo and Chinook), which was the other hot-side hop we used in our experiment.3

The difference between the two beers in our experiment were subtle, but I do think the enzyme-treated beer provided a better base for the tropical-leaning Vic Secret planned for the beer. But, knowing that some hops might do the opposite, as was found in the MBAA paper, it’s evident that more experimentation is needed! Part of what makes brewing so fun for me is using the brewing literature as a basis for experimentation. Whether it’s taking a natural wild yeast like M. reukaufii or playing with commercial enzymes for biotransformation, it continues to be one of the more exciting areas of hop science to me!

Footnotes

- Vervoort, Y., Herrera-Malaver, B., Mertens, S., Medina, V. G., Duitama, J., Michiels, L., . . . Verstrepen, K. J. (2016). Characterization of the recombinant Brettanomyces anomalus β-glucosidase and its potential for bioflavoring. J Appl Microbiol Journal of Applied Microbiology. doi:10.1111/jam.13200

- Meiners, L., & Cavanna, M. (2020). Using Exogenous Enzymes to Boost Biotransformation. Technical Quarterly, 57(1). doi:10.1094/tq-57-1-0330-01

- Takoi, K., Itoga, Y., Koie, K., Takayanagi, J., Kaneko, T., Watanabe, T., . . . Nomura, M. (2017). Systematic Analysis of Behavior of Hop-Derived Monoterpene Alcohols During Fermentation and New Classification of Geraniol-Rich Flavour Hops. BrewingScience, 70, 177-186.

-610x915.jpg)

In your Reukaufii-trois recipe the whirlpool addition seems to be a bit too high, roughly twice as much as a standard addition. Is that correct? Wasn’t the beer too bitter/astrigent as a result?

Also in the last recipe you mentioned Simcoe in the description and idaho 7 in the recipe.

That’s about 9 ounces for a batch trying to yield 5 gallons. Certainly on the higher end, but around 8 ounces per batch seems reasonable to me, but prefer more hot-side flavor and supporting bitterness (although at lower whirlpool temperatures you’ll get less IBU pickup). Thanks for catching the Simcoe mistake!

Thanks Scott for another great post! you’ve mentioned about Amarillo on the hot side for one of your hoppy forward beers and I haven’t been very successful with this hop in DH post-fermentation (usually paired with Galaxy). I don’t remember seeing this hop in the “Survivables” list either…any thoughts on how to better work with it? Thank you again

Just for some added info… the M. Reukaufii was sourced from the Oakland/Berkeley hills in the SF Bay Area during a yeast capture hike in November of 2018 organized by me and led/hosted by our friend Nick from The Yeast Bay. Our fellow hikers were given sterile tubes and together we collected various flowers, leaves, berries, etc. For more information on this hike and the strains we captured I suggest you check out Nick Impellitteri’s posts in the Milk The Funk facebook group. I (Tim Decker) have also posted there with photos from the hike. I’m really excited to see we managed to capture some cool microbes that day and I look forward to brewing with them myself soon. Thank you, Scott, for this great write up and experimenting with the capture.