Exploration of Post-Fermentation Hop Oils

Overview and Results of the Different Hop-variety Specific Oils

When new hop products hit the market, they are usually viewed with equal amount of excitement and confusion. Post-fermentation hop oils fall into this excitement confusion category for me. Are they supposed to replace dry-hopping all together? Are they just for the bigger breweries concerned with maximizing yields? How do you even get the oils to mix in beer evenly? Are they just for flavor and aroma or do they have other implications like mouthfeel and bitterness changes? These are the types of questions I’ll try to answer in this post. Attempting to research hop extracts and how they perform in beer was surprisingly challenging; most of the papers I could find focused more on the bittering capabilities of such hop products rather than flavor implications. Relying heavily on a few of the most recent papers on hop oils, interviews with the hop oil suppliers and academic authors on related studies, and my own personal experience, this article is hopefully a helpful starting point for brewers to start thinking about their own experiments with post-fermentation oil dosing!

Why Even Consider Hop Oils?

First of all, why even consider hop oils? One small but helpful reason to consider using hop extracts is the ability to store them in a small bottle at ambient temperatures for up to a year. At Sapwood Cellars, our cold room is stocked full of cans, boxes of pellets, and kegs. Another obvious benefit to brewers is increasing the yield of actual drinkable beer! I was much less concerned about this as a homebrewer, but getting a full 5-gallons (19-liters) out of an extremely hoppy beer is a nice perk. Essentially, efficiency is raised by using highly concentrated oils and less hops to lower the amount of hop material going into the kettle or fermenter and soaking up beer.

Another perk to hop oils focused on flavor and aroma is their ability to be used post-fermentation without causing any potential for hop-creep. Hop creep, for those unfamiliar, is essentially the ability of enzymes in hops themselves that can free up unfermentable sugars (dextrins), which can lead to re-fermentation. This re-fermentation can occur in an environment where little yeast is present (when dropping the cone for example), leading to off-flavors like diacetyl. All of the hop oils mentioned in this article have denatured these hop-creep inducing enzymes, allowing for pre-packaged use without fear of further re-fermentation.

Manufacturers of oils will often say that using post-fermentation oils can also help the shelf life of hop-forward beers. I always assumed that the presence of higher oils might mask or alter staling characteristics, but a 2011 paper dove a little deeper into stability. Specifically, the authors measured the staling aldehydes (bound aldehydes might be released over time, causing stale aged flavors) in the beers with and without oils. They found that beers with the hop oil essence had a generally lower concentration compared to those without. 1 The authors would not go as far as to say the hop oils have some sort of flavor stabilization mechanism, but it should be studied further.

But, beyond some practical reasons to experiment with hop extracts, I think the most critical question is whether they help make better beer? Increased yields are excellent; better extraction of oils into the kettle is also great, and not worrying about hop-creep is a perk. But, unless these are actually improving the beer quality (or at the very least maintaining the same quality while using fewer hops), I’m not sure I’d even consider using them!

Potential Concerns with Post-fermentation Hop Extracts

One of the issues with hop extracts is that they need to be emulsified to mix evenly into beer. On their own, hop oils, when added to beer, would likely float to the surface. Because of this, a carrying agent is needed to mix with the oils to make them soluble in the beer. Two of these common carriers are propylene glycol (1:100) or ethanol (1:10). For example, if you want to add a total of 5ppm of pure hop oil to your beer you would also be adding ~100 times that amount (500 ppm) of propylene glycol, which is still a very small percentage when you take into account your batch size.

Propylene glycol strikes me as an ingredient I’d prefer to keep out of beer. Still, it is widely used and approved by the FDA as a preservative and solvent in pharmaceuticals, saying it is “generally regarded as safe.” 1

Aside from the use of a carrier like glycol or ethanol (like Everclear) being used, there are factors to consider with oils like what hop-derived oils are being extracted because of their new soluble state (which can differ from straight up dry-hopping). In a discussion with Spencer Tielkemeier, East Division Lead and Brewing Innovations at Yakima Chief Hops, Spencer expressed this potential concern when I reached out to see if they had any extract products on the market.

Spencer’s main concern is that “the use of an emulsifier typically means that, by making the oil-soluble, you typically make EVERYTHING soluble. This means that oil fractions that would normally be gassed off or removed during a typical brewing process (i.e. hydrocarbons like myrcene and caryophyllene) are now fully soluble and present themselves in the finished product.”

“The end result is often a beer that shows interesting hop aroma, but is absolutely dominated by less pleasant woody and vegetal aromas from the hydrocarbons. Most other desirable aromas are masked by the sheer quantity of hydrocarbons. Beers produced in this manner often taste similar to chewing on a raw hop pellet. Interesting, but not exactly pleasant.”

Yakima Chief has experimented with creating a post-fermentation hop variety-specific oil extract from hop extract but has yet to release anything because their trials are exactly what Spencer was alluding to, hydrocarbon dominate beers with less than ideal carries for emulsifying. For now, their best product for late hop punch is their line of Cryo Hops®. To help explain some of Tielkemeier’s concerns with oils, the best place to start is comparing what is actually extracted when dry-hopping compared to using an emulsified oil.

What’s Extracting During a Dry-Hop?

For me to start thinking about hop oils and how they might differ from dry-hopping, I thought it was best to start with a paper from 2019 authored by Thomas Shellhammer and Dean Hauser at Oregon State University. In the paper, the authors dry-hopped at a rate of 1 pound per barrel with whole-cone hop varieties Amarillo, Cascade, and Centennial in a 24 hour dry-hop. First, the hops themselves were tested for total oil potential. After, the beer was tested for actual oil compounds extracted during the dry-hop. Finally, the spent hop material was tested again to see how much of the original hop oil potential still remained. The paper is great because it shows how inefficient dry-hopping can be in terms of oil extraction, something I think you’ll see is a major difference than using oils.

The graph of the results below is super interesting as you see how little of some of the hydrocarbons (some of the most volatile, green, resinous, and woody compounds) are making it into the beer during a dry-hop, despite taking up so much of the hop oils total oil percentage. In addition, the second chart listed makes it clear how many oils are wasted when dry-hopping with such a large percentage still residing in the spent dry-hops. As the paper’s authors conclude, “the results of this investigation provide proof that dry-hopping is a relatively inefficient process, and that spent dry hops waste on both a pilot and industrial-scale contain a considerable quantity of both volatile and non-volatile hop constituents.”

A great example above is with the hydrocarbon myrcene, the hops tested ranged from 371 to 2,382 mg/100g, by far one of the most significant portions of the hops total oils. Despite representing so much of the hop, only 14-25 ug/L of myrcene was tested in the final beers, with an amazing amount (258-2,163 mg/100g) remaining in the spent hops! In other words, only about 0.05% of the available myrcene from the hops are making it into the beer during the dry-hop. Although myrcene has recently been found to reside in hazy NEIPA’s at higher rates (as you’ll see below) you can see why dry-hopping with a variety like Citra, which is super high in myrcene, doesn’t give you an incredibly resinous and green result because so much of this compound isn’t finding it’s way into beer.

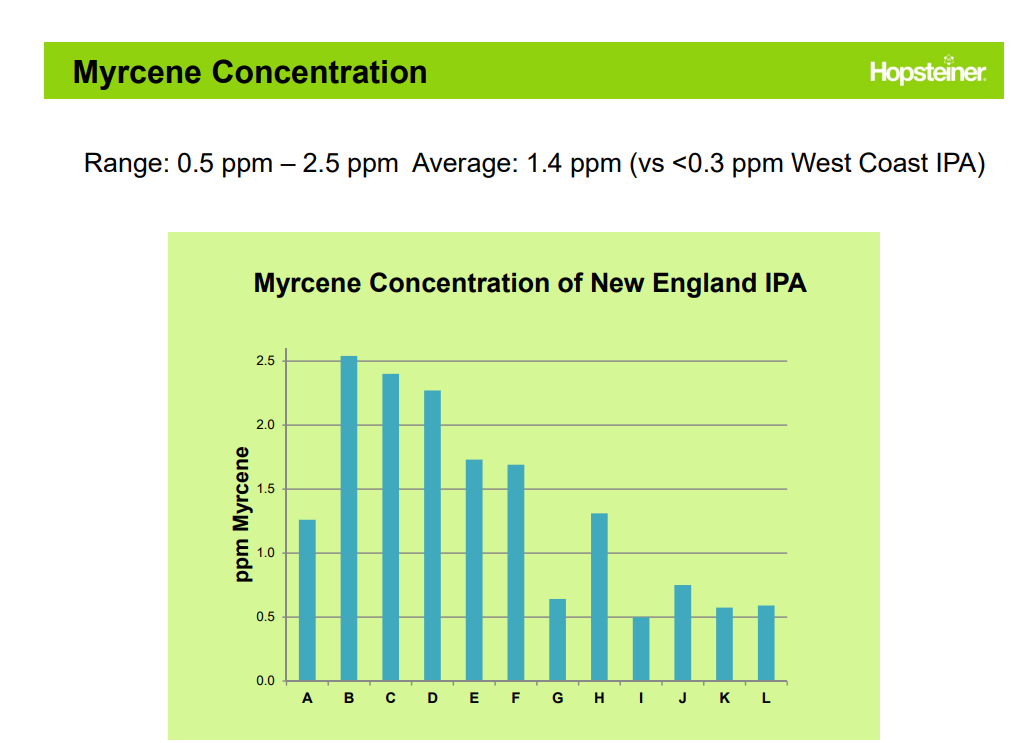

Just to help give you an example of how much myrcene is actually extracted into hazy beers on the commercial level (which is more than other styles, likely due to its viscosity) the chart below from Hopsteiner via Dr. John Paul Maye shows that in the hazy commercial IPAs tested, the maximum found was close to 2.5 ppm. 1Hidden secrets of the new england ipa. (2018). Technical Quarterly. “>https://doi.org/10.1094/tq-55-4-1218-01[/note] Keep in mind, this is considered to be a relatively high amount across beer styles.

You are probably fairly wondering why I’m so concerned with myrcene levels with dry-hopped beers. The answer falls into how drastically different hop oils are in their creation and extraction percentages. Some of the oils available claim a nearly 100% of the already emulsified oils could get into the beer when used post-fermentation. Hopsteiner suggests in their technical sheet on their oils, for example, that the recovery rate for certain aroma compounds can be as high as 95%, remember that the test above for only 0.05% of myrcene being retained!

To put this concept of oils vs pellets into a real-world application, consider dry-hopping with Citra which can be as high as 70% myrcene compared to using a Citra post-fermentation oil extract as many of these oils are now created from hop-specific varieties. If the ~70% of myrcene from Citra is extracting and staying in the beer from an oil extract, I would theorize that the result would be a complete resinous and green bomb of a beer that would be nearly impossible to achieve based on previous research with hop pellets alone.

Now, I don’t want to brag, but I sent a beer into Hopsteiner for Dr. John Paul Maye to test it for various compounds (results pictured below), including myrcene. I had over 2.5 times more myrcene than the highest commercial beer tested in Maye’s study for this particular beer. The beer that was tested was one that had zero hot-side hopping done but was hit with an ounce of hops during fermentation and another 8 ounces of dry-hops (split between Citra and Amarillo) late and post-fermentation (for a 5-gallon (19L) test batch). I theorize that the lack of hot-side hopping allows for greater retention of hydrocarbons like myrcene with big dry-hop loads. The result of which, in my opinion, is not a very good beer that comes across as very vegetal and one-note. I bring this particular beer up just to show that a super myrcene-heavy beer with dry-hops alone wasn’t very good with too much resinous vegetal notes in my opinion and oils could theoretically achieve even higher rates.

Nothing is wrong in my opinion with myrcene per se, I think a certain amount of it can help to give that fresh green out of the bag dry-hop experience. However, when getting such high extraction efficiency with oils (or even in my case with no hot-side hopping and heavy dry-hopping) it seems logical that the oils would put these myrcene levels (to stay with the example) at rates never really seen in beers before. This is particularly troubling as one paper found that myrcene at even low levels resulted in metallic and geranium-like aroma notes concentrations at just 0.86 ppm. 1

Solubility Maximums

Is it even possible for 100% of an oil extract and all the compounds residing in it (like myrcene) to extract into the beer? In a conversation with Thomas Shellhammer and Dean Hauser, who authored the paper above on dry-hopping efficiency, they explained to me that this isn’t likely the case. Solubility maximum is a concept where if something is already saturated to the max, adding more won’t reside in any more of that particular compound into the liquid phase because it simply can’t get into solution anymore. It’s kind of like if you jump into a lake with all of your clothes on, jumping in a second and third time won’t get you any wetter!

To give you an example of how far away dry-hopping alone is getting you to maximum thresholds, consider the following results from the OSU study discussed above (done at 1 pound per bbl). The linalool found in the test beers ranged from .08-0.281 ppm, nowhere near the max solubility of ~1,500 ppm. The same for myrcene, where the test beers ranged from 0.014-0.025 ppm, again, nowhere near their maximum ranges of ~10 ppm.

Although to date, no testing that I’m aware of has looked at using post-fermentation hop variety specific oils and measured dosed beer before and after to see the exact extraction efficiency rates. Hopefully, we can get this tested in the future to see if using oils gets us closer to the solubility maximum for some of the essential oil compounds. The question of if we even want to be near these maximums is a good one. But even just getting a better sense of the oil potential in post-fermentation oils to the resulting amounts in the actual beer would be super helpful as these products advance.

If there is a solubility maximum when dosing oils, should we even be worried about overdosing? It makes sense to me that if you can’t even get certain oils into the beer over certain limits, you theoretically could just pump in the oils until they are saturated and the non-saturated just kind of disappear? That’s probably not the case either, says Shellhamer. There still could be an impact of dosing oils over their limits despite not being the liquid phase of the beer. For example, you’d probably taste these extra compounds when they warm in your mouth. Despite not being in the beer, they are still there to some degree, likely on the surface.

In different benchtop dosing trials at Sapwood with varying amounts of certain post-fermentation oils to beer, I suspect some of these non-solubilized oil flavors impacted the samples. When we went too high with the dosing rate, we could taste strong extracty-like flavors. It would be interesting to see if the compounds were at or near their respective solubility maximum. Still, it was clear that too many of these oils started to lose variety-specific flavors, and the beer would taste generically green and herbal. In other words, the higher the dosage rate, the more the beer would taste the way the extract smelled out of the container.

Analyzing the Sensory Experience of the Different Hop Oil Classes in Extracts

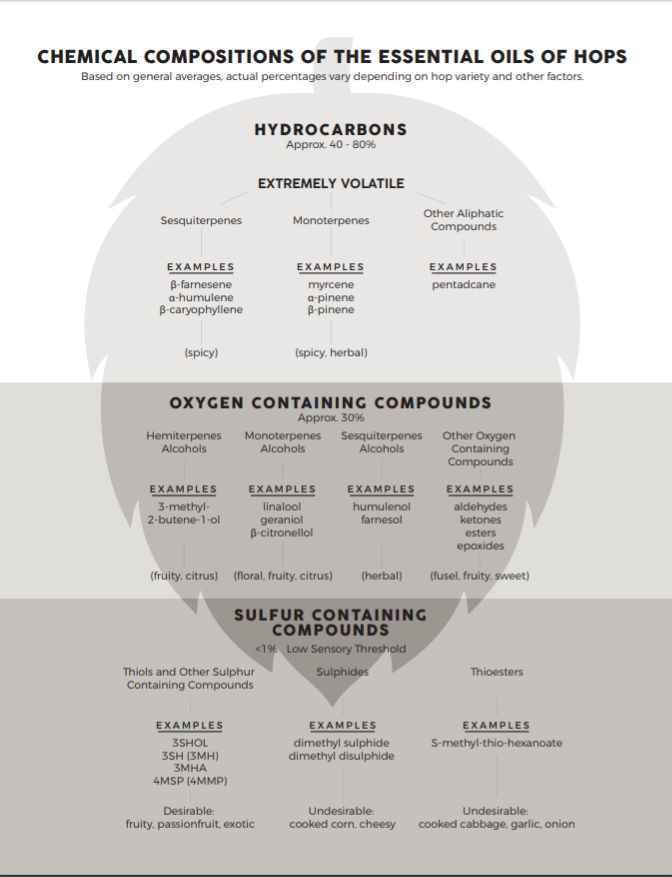

Before diving into the different hop oil extracts on the market and some of our experiences with them, it’s interesting to look at a 2021 paper that examined how the individual sets or fractions of hop oils can impact beer. For help with a visual on the different hop classes and how the generally represent the total oils in hops, below is a chart I had made when writing The New IPA, which helps to reference as the results of this study are described.

Keeping in mind the different classes of oils in the chart above, the work done in the Journal of the Institute of Brewing really helps to illustrate how greater extraction of certain classes over others in hops oils may have big impact on the overall flavors and mouthfeel impacts in the beer. The authors used Magnum hop oil and analyzed the specific fractions of oils in a pale lager beer. The fractions of oils separated out and tested by a sensory panel included sesquiterpenes, terpene alcohols, humulene epoxides, and monoterpene alcohols sesquiterpene alcohols, humulol +, humulenol II, linalool, geraniol, and caryophyllene oxide. 1 They didn’t test a Magnum hop extract as a whole (all of the oils together). Instead, they fractioned off the oils and did a sensory tests individually. This type of examination is helpful because it can show how a greater extraction of some the fractions (like hydrocarbons) when dosing with oils vs. dry-hopping might impact the beer.

When it came to overall aroma and flavor intensity, the geraniol and terpene alcohol fraction scored the highest, and the caryophyllene oxide and humulene epoxides fractions were the lowest. Likely, the higher scores for geraniol and terpene alcohol fraction could be because of their respective flavor thresholds and the more polar nature, allowing them volatile less than other compounds. The geraniol and terpene alcohol fraction also increased the perceived sweetness intensity in the beers.

The panel found this sweeter and fruity fraction associated with descriptors as lemon, pinewood, soapy, rose water, orange fruit, and grapefruit. Interestingly, linalool (which is often a marker for “hoppiness”) was not found to be strongly characterized by and particular flavor or aroma term, and it’s likely more of a flavor enhancer as it relates to dosage via hop oils. Also interesting was that the malt character of the lager beer was not found to be impacted much by adding the various fractions of oils.

As it relates to bitterness perception, the authors found that the sesquiterpene fraction flavored beer had the highest scores for “harsh bitterness.” Whereas the beer spike with the geraniol fraction had the highest scores for “smooth bitterness.” Specific compounds that were found to increase harshness were a-humulene, δ-cadinene, β-caryophyllene, β-myrcene, and caryophyllene oxide, and the combination of compounds could drive the bitterness sensation.

As it relates to astringency (a common issue in some hazy IPAs), the highest oil fraction was the humulene epoxide beer. The results aren’t entirely surprising, considering that humulene epoxide is part of the spicy sesquiterpenoid fraction of hops.

An email exchange with Christina Dietz, an author on the paper in discussion (also part of her Ph.D. project), helped give some further insight into their sensory results of the Magnum hop oil. For example, regarding the greener hydrocarbons masking fruitier flavors, Dietz shared that this may be true for some extracts (of specific hop varieties) but others, these fruitier compounds can be in concentrations too low to be noticed, rather than being masked. This suggests that the hop variety used can make a difference as the fruitier the pellet, the likely fruitier the oil. But indeed, their results did find that “other compounds inducing “green” flavors (musty, earthy, woody, grassy) were found to be involved in harsh, bitter notes and astringency.”

However, Dietz explained that just because some of their results pointed to certain oil classes being more bitter and having certain mouthfeel implications, this should not necessarily be seen as a full-scale bad thing. The “harsh bitterness and mouthfeel characters would certainly fit with other beer styles.”

I asked Dietz about her thoughts surrounding potential solubility maximums with hop oils dosed post-fermentation. According to their tests, using calculations, they can confirm that the hop oil fractions did not 100% solubilize into the beer. Dietz explained that “whether a hop extract is 100% or near 100% soluble highly depends on the polarity of the matrix and the polarity of the hop oil compounds.” This logic makes sense to me, especially when thinking about hazy IPAs and post-fermentation oils. I would guess that the more viscous nature of the hazy IPA would enhance the retention of some of these otherwise volatile compounds (like myrcene as found by Maye above) and still push them way past what you would get when dry-hopping with pellets alone.

It’s interesting to consider the different sensory thresholds when you take into account the matrix to which the compounds are being tested. In other words, it would make sense that dosing a post-fermentation hop oil into water at the same rate as dosing into a hazy IPA would yield different results. Dietz explained to me that different sensory approaches and variables involved in the testing could impact results like the different types or styles of beer the oil is tested in, other tasting protocols, panel sizes, and statistical analysis approaches. Even the definition of “sensory threshold” can impact results (orthonasal, retronasal, detection threshold, recongition threshold, etc.).

I like to mention Dietz comments on the complications of different tasting matrixes because even in our small trials with the various oils at Sapwood, we got completely different results when dosing in an unhopped lager vs. a heavily dry-hopped NEIPA, for example. To me, the lager with the oil, although subtle, didn’t add to the beer but instead stood out in more of an artificial way. In contrast, oils dosed in the beer named Full Measure (described below) added to the complexity already in the beer to help complement and amplify what was already there.

I appreciate the work done by Dietz and her colleagues, in part, because it gives a great baseline of how these different oil classes might impact a beer and helps to think about how to alter some of these oils to make them fit certain situations or beer styles better than others.

For those that tend to be more of a visual learner, below is an interactive chart I created to help explain the results of the study above showing which hop compound classes had what type of sensory impact on the test beers.

Totally Natural Solutions

Finally, lets talk about some actual hop products with some results! I’m starting here with Totally Natural Solutions (TNS) because in terms of the different oil extract products out there, TNS has the unique ability through their proprietary processes to alter the concentrations of these different hop compound classes. Essentially, their oils undergo the same steam distillation process to isolate hop oils, but at this point using their patented fractionation to fine-tune the total oil makeup. In other words, this fractionation technology allows them to alter individual classes of oils, allowing for true-to-type hop variety character (raising/lowering the specific oils to more closely resemble the hop itself). Or, another potential use is they could potentially back down entire fractions (like sesquiterpenes), allowing compounds like monoterpene alcohols to potentially sing more by not having to compete with strong green flavors. Essentially, think about the paper discussed above looking at which classes of oils impact a beer in certain ways and then reducing or eliminating some of those classes to achieve potentially better results.

Totally Natural Solutions likes this combination approach to creating their oils because it’s a solvent-free way to mimic varieties at different parts in the brewing process. Suppose you have the ability to lower hydrocarbons like myrcene using fractionation technology. In that case, you could potentially more closely resemble using a hop during the whirlpool where a large percentage of myrcene would otherwise be removed due to steam in the kettle, trub, and active fermentation (this is the idea behind their HopShot® line of oils whereas their HopBurst® line isn’t fractionlized). Depending on how this actually translates into beer, it sounds exciting to give brewers a targeted method for amping up their beers post-fermentation if they lack hop saturated flavor or if the dry-hop was more lackluster than anticipated.

If the terminology of these oil fractions sounds familiar from earlier in this post, it’s likely because two of the authors of the paper have ties to Totally Natural Solutions. Pedro Oliveria is the technical Director, and Colin Wilson is the Managing Director of TNS. It makes total sense to me that a company with the capability of adjusting entire hop fractions from a steam-distilled extract might be curious how these hop fractions are realized on the palate. For example, if sesquiterpenes are responsible for some negative aspects of oil use, like increased bitterness and musty, earthy flavors, why not lower this fraction to make the hop oil more approachable?

In collaboration with New Zealand Hops and Totally Natural Solutions we brewed up another beer at Sapwood, trying to work on a larger scale some of what we learned in smaller experiments. For the beer that was eventually called Full Measure, we went full-on Nelson Sauvin! We mash hopped with .2 pounds per bbl (1 g/L) of Nelson Sauvin, followed that up with 2.2 pounds per bbl (~8.5 g/L) of Nelson Sauvin in a 180°F (82°C) whirlpool, and finally double-dry-hopped it with 3.3 pounds per barrel (12.5 g/L) of Nelson Sauvin post-fermentation. Finally, we then did benchtop trials dosing Nelson Sauvin oils from TNS into individual glasses to ultimately dose 10 grams/hL of Nelson Sauvin (called Victory) HotShot® and 10 grams/hL of Nelson Sauvin HopBurst® made it into the beer.

The result was one of the punchier pale ales we’ve ever brewed, it didn’t hurt that the Nelson smelled great from the start. Here’s what the Untappd drinkers had to say regarding Full Measure. It was interesting when dosing the beer in smaller trials, going above that 10 grams/hL of the HopBurst® (which isn’t fractionalized) really started to increase the bitterness perception and start to get “extracty.” The Fractionalized HopShot® was much tamer and I liked the overall brightness it brought to the beer without too much of the green-leaning characteristics.

In a collaboration between Other Half Brewing and Sapwood, we asked TNS if they could make us a custom oil after getting a chance to work with their Nelson Sauvin options. Using the same logic explained so far in the post, the ask of TNS was to use their fractionalization technology to create an oil 100% from Simcoe hops (which is called Geronimo from the HopBurst® line) as the reference hop profile. From here, TNS “fractionate heads/tails and optimize the oil to spike fruity fractions”. The hopeful result is a lighter lower myrcene impact type of profile that will tend to be closer to what both breweries were looking for from the oil. Essentially, we wanted more of a saturated fruity hop top note to amplify the Simcoe T-90 and Simcoe Cryo® dry-hopping. It makes sense to me to experiment by fractioning down those compounds that might increase bitterness (sesquiterpene fractions), harsh bitterness (humulene epoxides), musty aromas (humulene epoxides and sesquiterpenes), and earthy aromas (also sesquiterpene fraction)–especially when you consider so much of the oil is soluble compared to dry-hopping with pellets. The end result was great, a super punchy Simcoe-forward beer that doesn’t come across as extract-like, but seemed to just enhance the Simcoe already in the dry-hop. The reduced hydrocarbon makeup of the oil seemed to be a big improvement in terms of getting a truer-dry-hop-like flavor.

In an all Motueka™ dry-hopped DIPA, we gave their HopBurst® Limonata (derived from Motueka hops) a shot. After fermentation and dry-hopping (4.4 pounds per barrel or ~17 g/L), we did some benchtop trials of different dosing rates and decided to dose the tank with 300 mL of Limonata. On the higher end of 500 mL (assuming about 19 bbls (2,229 liters) of beer in the tank) it was immediately brighter and bolder, but it started to move away from what I like about Motueka and got a little Dawn dishsoap-like and what I thought was a little bit more of a lingering bitterness. I kind of wish I would of ordered the HopShot® product (fractionalized to reduce some of the greener compounds) as it might have been better for this particular beer (and maybe most post-fermentation). On the lower end (300 mL) it seemed to liven up the beer, reduce a slight hop-spice thing it had going on.

We also trialed their Outback (Galaxy) HopBurst® oil in an IPA that was dry-hopped with Galaxy®, Hydra™ (Great Lake Hops), Vic Secret™. Hydra to is a hop that reminded me a bit of Galaxy in some sample packs we received, much like Vic Secret has done in the past, so we figured it would be a fun combination with the Outback oil. Again, I wondered if the fractionalized would have been better to lessen some of the green-leaning hydrocarbons because any dosing rate above 200 mL (again assuming ~19 bbls (2,229 liters) left in the tank after dry-hopping) started to change the fun fruit-striped gum aroma to a slightly piney one (albeit with a brighter overall aroma).

Hopsteiner

Talking with Dr. John Paul Maye, Technical Director at Hopsteiner, they currently use two methods to produce their post-fermentation oils. The various techniques for creating aroma hop extracts appear to be two main methods for making the oils. The first is steam distillation, which is considered the traditional way of making hop oils. Steam distillation takes leaf hops, boils them in water, condenses the vapor, and isolates the oils (this process is called oil type dry in Germany).

The second method of creating hop oils is called thin-film evaporation. During the process, CO2 hop extract goes through a thin film evaporator where the extract is under vacuum, and the oil is separated from the extract. One benefit to thin-film evaporation is the price (typically around $2/gram from Hopsteiner). The lower price is due, in part, to the ability to use a byproduct of creating the oils.

What compounds do these oils contain? Hopsteiner’s spec sheet indicates that for both thin-filmed and steam-distilled oils, the majority of the compounds are comprised of myrcene, humulene, caryophyllene, and farnesene (part of the sesquiterpene fraction) which makes sense when you consider these compounds usually represent a larger percentage of a hops total oils. However, if we consider the results of the charts above on how the individual compound classes of hops impacted taste perceptions, oils high in this sesquiterpene fraction might start to produce harsh bitterness, astringency, grassy, earthy, and musty flavors if used in too high of concentrations.

However, Maye also shared that some brewers were getting better flavor from the oils when they were added prior to maturation (so with some active fermentation still taking place). This concept makes sense to me as more of these more volatile sesquiterpenes would be removed with vigorous CO2 scrubbing, yeast, and other factors, leaving behind more polar and fruity compounds. In addition, by adding oils like Hopsteiner’s before maturation (and before dry-hopping) you may also get scrubbing of these sesquiterpenes by the leaf material coming from dry-hopping as the green material can absorb and remove many of these non-polar hop compounds allowing better flavor results from the oil.

Now, which one of these two processes (thin-filmed vs. steam distillation) is best for the hop oils themselves? I asked, Dr. Maye this exact question. “Some people like the thin film because it operates under vacuum and at temperatures hotter than 100°C, therefore it can pull-off more hop oil that steam distillation doesn’t. The only downside of thin distillation is the number of varieties is limited (because they have to already be in extract form) whereas steam distillation there is no limit.”

As I was preparing for this article, Hopsteiner sent me Centennial extract samples of thin-filmed and steam distillation samples. I opted to get the pre-emulsified versions (diluted 1:100 in propylene glycol) of each to make it easier to add them to individual kegs post-fermentation. I took 10-gallons of fermented IPA wort from a tank before dry-hopping and split them into two 5-gallon kegs. I added 3.5 grams of each oil inline as I transferred from one keg to another to help the thin-filmed and steam distillation oil mix evenly. This rate of ~.4grams/gallon (10grams/hL) is in the middle range of the end of their suggested use for ales.

The impact was relatively subtle at this 10 grams/hL dosage rate for both of the oils. I think this is especially true when there isn’t any dry-hopping taking place (which I did in this case to get a better idea of how the oils perform). Neither of the oils screamed dry-hopped flavor to us at the rate, but there was a small difference between the oils. The Thin-filmed oil was slightly more subdued in overall aroma and had a slight botanical thing going on. The steam-distilled Centennial oil beer was a little more centennial-like and popped a little more aromatically with a slightly less grainy malt character coming through.

At least for these two test beers, complete replacement of dry-hop character isn’t going to happen (which isn’t the point of them anyway). Although Maye told me that one brewer reported a mix of 3 ppm Lemondrop hop oil and 3 ppm Sultana hop oil resembled more of a typical dry-hop character, which potentially suggests the mix of oils may also be a good place to experiment with. Clearly, the dosage rate is going to have an impact on how much the oils shine, but at least for these samples, being closer to the 20 grams/hL seems like a better target.

Glacier Hops Ranch Hopzoil™

Another potential post-fermentation hop oil extract on the market is from Glacier Hops Ranch called Hopzoil™. Similar to the extracts created from Hopsteiner, Hopzoil™ is more akin to a total oil extract, meaning the oil is more likely to resemble the hop it’s created from (but they are not trying to completely mimick the starting hop’s profile). Tom Britz, Founder and CEO of Glacier Hops Ranch, entertained some of my questions via email as I was trying to get a better sense of how their oils were created and how they might be best utilized.

Tom explained that their oils are created by pure steam distillation from fresh whole hop cones after they are harvested. They see them as having a sensory benefit compared to making oils with pellets with supercritical CO2 technology. In addition to using individual hop variety oils, they also have created hop blends that target specific aromatic profiles, like the Citrus Fruitbomb™ I trialed in a small batch explained below. None of these oils, including the blends, contain alpha or beta acids. This is one area where Hopzoil™ is unique in that the lack of alpha-acids allows for potential use in the whirlpool without worrying about bittering. Although intended more as a cold-side hop product, I’m always a fan of the concept of trying to load up the fermenter with a diverse set of hop compounds to layer in hop saturated flavor to go with heavy dry-hopping.

Tom also shared with me that the oils do, in fact, contain hop-derived thiols, which is intriguing as they can have strong impacts on beer even when dosed in small amounts based on their low sensory thresholds. Although the oils haven’t been tested that I’m aware for actual thiol counts (or thiol precersours), this is something to keep an eye on as a great way to get emulsified thiols into solution. I would be especially interested (and this goes for all the oils in the post) if any measured thiol precursors (discussed in a previous post) as those would be great candidates when paired with a GE yeast strain designed to unlock the thiols during fermentation.

Just like with Hopsteiner, Hopzoil™ does come pre-emulsified which makes adding it to beer much easier as oil on its own would want to float and not extract into the beer. If you’d prefer to dilute the oil yourself, they also sell a “pure” format. Their “Majik” and “Hazy” line of oils are the pre-emulsified versions.

In a video discussing a trial of Hopzoil™, it was estimated that 3/4-1 pound of hops equals ~4.5-5mL of oil (~a 4.5 x oil ratio). I like looking at this type of ratio to help get a sense of how many hops you might be using with oil. In terms of dosage recommendations, a good starting point is 2.5-5mL/BBL based on the discussions in the video.

I tried dosing multiple 5-gallon kegs with different oils from Glacier Hops Ranch to get a sense of how they translate into fermented beer. I went super high on nearly 2.5x the suggested amount for the first set of trials to force their flavors a bit (especially after going too low on the Hopsteiner trials). All of the oils were again dosed into 5-gallon kegs of beer post-fermentation. We did separate addition of their Azacca, Amarillo, and Centennial oils for the trials, which all gave distinguishable characteristics.

Although you can see what our customers who visited the taproom that particular day, the Amarillo oil was the most green and plant stem-like, which bordered a little oniony as it warmed up. I’m assuming the aroma of this particular one might be improved with a lower dosage rate or even active fermentation. Not relevant, but Amarillo has been a tough hop for us to use the past couple of yeast as it’s just not been up to the standard we were used to using only a handful of years ago (German Amarillo has been one of the better ones). The Centennial oil was one of our favorites as it had a nice bright orange character that stood out as the top note. The Azacca oil beer seemed to lighten/brighten up the beer, likely masking some of the doughness/vanilla character we can get from RVA Manchester, but it wasn’t particularly Azacca-like in any distinguishable way.

We also did a 5-gallon trial of one of Glacier Hops Ranch blended oil offerings called Citrus Fruitbomb™. It’s unclear what hops make up the blend, but it’s advertised as an “explosively citrusy blend featuring several fruit-forward varieties.” In general, I’m always a little leery of hop blends of any kind because I can’t help to think they are blended because they aren’t selling on their own, but in this case, I’m interested as Hopsteiner found that when brewers were using multiple oils made from different hop varieties, the results mimicked a more authentic dry-hop character.

For the F-bomb blend, we chose a simple pilsner base that was not dry-hopped, I again went a little high on the dosage, choosing ~.38 grams/gallon. I expected the aroma to be a little more potent at the dosage, but it was again relatively subtle. However, there was a difference from the base beer; the oils gave the pilsner an orange/lemon zest aroma. This particular beer had a noticeable mouthfeel impact from the oil, which I noticed in a few of the other trials at the brewery. There’s an oil slickness to the mouthfeel with a trailing extract-like resinous quality that sticks to the roof of your mouth after swallowing. To me, the aftertaste doesn’t read hoppy; instead, it reads extract-like. I’m sure adjusting the dosage rate might help with this, but likely at the cost of the citrus aroma.

Other Market Options

It’s worth mentioning a few other companies that are creating hop oils (or will soon release), but I just haven’t had the chance yet to experiment with them. I had a good conversation with SORSE Technology in Sapwood’s tasting room about their hop variety-specific oils that will soon be available for brewers. Like with some of the other oils, they have a full spectrum approach, meaning the oil closely resembles that of the hop it’s created from. Unique to SORSE is their natural emulsifier, which avoids the use of propylene glycol. SORSE also has access to great hop varieties, so I imagine some of their future offerings will be appealing, especially if they decide to fractionalize to reduce some greener and harsher components.

As I write this post, another company coming to my attention is Oast House Oils located in Lafayette, Colorado. Their oils are intended for cold-side flavor and created via supercritical CO2 extraction. Currently, they have oils available for Amarillo®, Azacca®, Cascade, Cashmere, El Dorado®, Huell Melon, and Mandarina Bavaria. A great Craft Beer & Brewing podcast with Brandon Capps of New Image Brewing dives deep into his experience with Oast House oils and is definitely worth a listen!

BarthHaas also has an oil product intended for a dry-hopping boost called Spectrum, which is available for Citra®, HBC 394 c.v. and Mosaic®. Spectrum is unique in that it’s advertised as being 100% from hop material with no emulsifier needed (contains ~30% water). Spectrum doesn’t contain iso-alpha acids or humulinones (it does contain polyphenols), so there’s no risk of additional bitterness. However, it does have some alpha-acids, so using it in the kettle could result in IBU pickup. BarthHass recommends first dosing the oil in 5-10 times the weight in water and stirred to disperse evenly.

We’ve used the Citra® Spectrum product in a batch of triple IPA at Sapwood. In our experience, pre-mixing seems critical as dropping just a little bit in the water, the oil sank and remained in one solid chunk. It took a lot of stirring to get the oil to break up and homogenize in the pre-mix water. I could imagine this thick oil just sinking in your tank without trying to break it up first. We added the oil on day 3 of fermentation in hopes of dialing back some of the resinous and green extract-like characteristics you can get from these types of oils. I will say the Spectrum oil smelled better straight up than most of the oils we played with, perhaps because it’s 100% hops? Because we were using it during active fermentation, we weren’t afraid to go on the higher end of their suggested dosing rate of 0.5-1 ml oil per hL. We dosed at 500 mL of oil for a 20 bbl batch (2,347 liters). Because Spectrum is ~8% oil, our rate would be approximately 1.68 mL oil per hL.

In this one experience with Spectrum, I think it did add a subtle bit of flavor complexity. Despite being used cold-side, the active fermentation addition seems to help reduce the harsh edges of the oil while providing the perception of hot-side flavor with just a little bit of an aroma push. We plan to continue experimenting with the rest of our jug in a future beer!

Like with all these oils, figuring out how to use them (post-fermentation, active fermentation, or in the kettle), how much to add, and what beers might benefit from them is the challenge for brewers! So far, I see these oils as another tool, mainly for boosting dry-hop aroma by adding a top note to already dry-hopped beer. Or as a way to increase the saturated flavor needed to balance a heavily dry-hopped beer. I hope to see future papers looking even closer at post-fermentation hop oils and what exact compounds are being retained and at what levels. Particularly when it comes to thiols and thiol precursors as adding these with GE yeast strains in the kettle or at the start of fermentation could yield fun results!

Cheers!

Scott

Key Findings

- Post-fermentation oils can offer a last-minute hop burst without the risk of hop-creep.

- Typically, hop oils are emulsified x100 the weight of oil with propylene glycol.

- Hop oils may extend the shelf life of hoppy beers by reducing the amounts of staling aldehydes.

- During a dry-hop with T-90 pellets, very little of the hydrocarbons (like myrcene) is retained, but the emulsified oils will likely be retained at much higher concentrations with hop oils.

- When looking at hop oil fractions, monoterpene alcohols (like geraniol) increased the perceived sweetness, had a smooth bitterness, and was perceived as fruity (orange fruit, grapefruit, and lemon). In contrast, the sesquiterpene fraction of hop oil was associated with harsh bitterness and astringency.

- Hop variety-specific hop oils made to mimic the overall oil profile of the source hop would likely come across more resinous, green, and astringent compared to normal dry-hopping thanks to higher retention of compounds like a-humulene, δ-cadinene, β-caryophyllene, β-myrcene, and caryophyllene oxide.

- Dosing hop-oils that mimick the source hop oil makeup might be better used in the kettle or during active fermentation to help scrub the high concentrations of solubilized hydrocarbons. Oils that don’t contain alpha-acids can also be used in the whirlpool to increase hop oils getting into the fermenter without the bitterness increase.

- It makes the most sense to experiment with post-fermentation hop oils in small amounts in a glass and scale it up to dose the batch. Too little, and it seems like you don’t get much of an impact, but too much, and it can be detrimental!

Below is a chart of some of the oils that are now available to experiment with!

Post-Fermentation Hop Oils

-610x915.jpg)

For the TNS Hopburst varieties like Simcoe or Galaxy, how many g/L of T90 pellets would you say is equivalent aroma-wise to 10g/hL of oil?

It’s tricky to say for sure, but in a similar question to them and TNS responded, “Pellet initial oil content (~1%) x extract brew yield (~33%) but likely will not provide 100% match to taste delivery due to differences on selective components extracted.”

So that would be 3.000 g of pellets with 1% total oil, considering 33% extraction, to match the 10 g/hL of oil?

Hi Scott, I read you book, watched your interview on BeerSmith, and this article, very good work. I dry hop in a 5 gallon keg. I’m interested in how you added the hop extracts to your kegs without opening up the keg, it sounds like you use some type of fixture to inject the extracts thru the ball locks. Could you provide more detail on the keg process. Secondly, since extracts use very little amounts, I’m thinking about using drops as a volume/weight, do you have any experience with using drops and what would you consider the volume/weight of a drop to be??

I have a german pils that ending up being not as bitter as I wanted to, could I use the ISO Extract from TNS to up the bitterness to the finished beer in keg. What would a dosing rate look like for this product?