London Ale III | RVA 132 Manchester

It’s no secret that London Ale III (Wyeast 1318) has been a favorite among homebrewers for super juicy New England style IPAs. I can think of three possible reasons why the strain appears to work so well in these beers:

- Seemingly natural ability to leave a soft and smooth mouthfeel (possibly higher glycerol production)

- Both strains are advertised as high flocculating yeasts, which generally means the beer clears up as the yeast cells adhere to form flocs and either rise to the surface or drop to the bottom of the fermenter. However, strangely in the case of dry hopped NE style IPAs with these strains, they do not clear up at all. Some have reported these strains clear up just fine without dry hops. It’s possible this may have the added benefit of leaving more hop oils in suspension along with the yeast as less of the yeast cells are striping the oils. It’s unclear to me so far as to why exactly these beers are so hazy after dry hopping. Flocculation is complicated processes affected by numerous parameters such as nutrient conditions, dissolved oxygen, pH, fermentation temperature, and yeast handling and storage conditions.1Part of the haze may be coming from the higher level of chloride I’m incorporating to enhance the mouthfeel’s softeness, as higher chloride levels has been found to hinder yeast flocculation.2 In addition, the increased chloride levels is in part because high sulfate levels has been found to have a “clear negative correlation” to perceived hop flavors.3

- The lower attenuation you get with the strain seems to combine to do a few things like boost the perceived sweetness, increase the mouthfeel, and keep the beer from getting to dry, which in my opinion can increase the bitterness perception. Although I’ve had many beers finish rather high, but still come across dry on the palate.

London Ale III has always been rumored to stem from Boddington Brewery originally located in Manchester. Nicknamed (given by the brewery itself) in the 1990’s, “The Cream of Manchester,” there is a big clue that the brewery itself considered their beers to have an incredibly soft palate, thanks in large part to their yeast strain.4 But does London Ale III really stem from the Boddington strain? After all, why would it be called London Ale III if it’s from Manchester? I’m not good with geography, but I have Google Maps, and London and Manchester are about 200 miles away from each other!

RVA is a relatively new yeast lab located in Richmond, Virginia and one of their many strains happens to be (and this is exactly how they list it on their website) RVA 132 Manchester Ale (Boddington). Now that leaves no guessing, this strain is in fact a Boddington strain from Manchester!

The two strains sure seen to be pretty similar in terms of the commercial descriptions:

Wyeast 1318 | RVA 132

Flocculation: High | High

Attenuation: 71-75% | 70-75%

Suggested Fermentation Temperature: 64-74F | 65-72F

Alcohol Tolerance: 10% ABV | 10% ABV

I decided to do a side-by-side of the two strains and see for myself how they compare in a New England Style IPA. Keep in mind this isn’t a proper side-by-side, although the two beers shared the same mash, grist, and fermentation temperatures, I chose slightly different hops for the dry hops as well as allowed one of the beers to have a higher original gravity (I needed to brew two different beers for the National Homebrew Competition and I didn’t want 10 gallons of the same beer on tap). To do this, both beers were mashed together and ran off into two separate boil pots. One of the boil pots (the one I needed to be in IPA territory for purposes of the competition) I allowed more of the first runnings in, which of course raised the original gravity. I then allowed more of the sparge runnings into the second beer, which lowered its original gravity top pale ale territory.

The RVA Manchester Ale yeast went into the slightly lower gravity beer and was dry hopped with Amarillo and Citra and the London Ale III beer went into the slightly higher gravity beer and was dry hopped with Galaxy and Citra. Both beer’s turned out great (more specifics below), but the RVA yeast produced an incredibly flavorful beer that had a touch of vanilla that I’m quite certain is a yeast derived flavor/aroma. The London Ale III beer was great too, but there was a clear difference in the two strains which was easy to pickup on despite having different dry hops. I personally liked the RVA beer better, but the London Ale III beer placed 1st in the American IPA category advancing to the finals in this years American Homebrewers Association Competition in the Philadelphia judging center. Despite comments from the judges like “soupy clarity – excessive for hop haze” and “hazy” the beer won out in the mini-Best of Show round against likely clearer beers, which in part shows that this cloudier beer style does come with increased hop flavor. As this haze is truly a product of the NEIPA brewing process and yeast selection and not an intended end goal.

RVA Manchester Amarillo/Citra | London Ale III Galaxy/Citra

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 45 min | 69.8 IBUs | 5.2 SRM | 1.058 | 1.017 | 5.4 % |

| Actuals | 1.053 | 1.014 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Organic 2-Row | 9.849 lbs | 67.24 |

| Malted Spelt | 3.444 lbs | 23.51 |

| Caramel/Crystal Malt - 20L | 12.54 oz | 5.35 |

| Cara-Pils/Dextrine | 7.87 oz | 3.36 |

| Acid Malt | 1.25 oz | 0.53 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Dr. Rudi | 40 g | 45 min | Boil | Pellet | 11 |

| Citra | 35 g | 15 min | Aroma | Pellet | 12 |

| El Dorado | 35 g | 15 min | Aroma | Pellet | 15.7 |

| Citra | 110 g | 0 min | Dry Hop | Pellet | 12 |

| Amarillo | 56 g | 0 min | Dry Hop | Pellet | 9.2 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Calcium Chloride | 5.65 g | 60 min | Mash | Water Agent |

| Calcium Chloride | 4.25 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 3.70 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 2.80 g | 60 min | Mash | Water Agent |

Mash

| Step | Temperature | Time |

|---|---|---|

| Mash In | 155°F | 60 min |

Notes

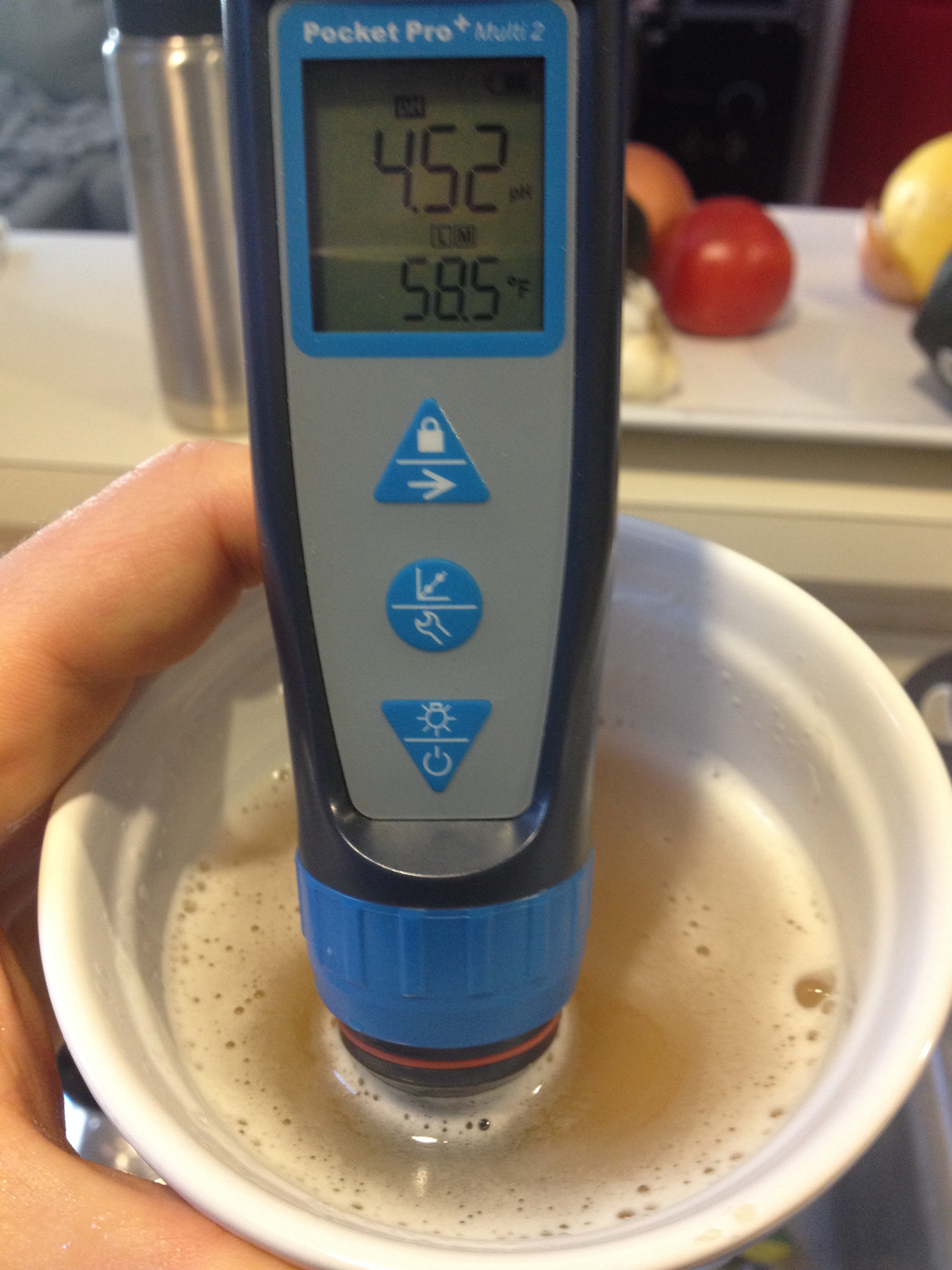

| Water: .75 g/gallon gypsum & 1.0 g/gallon calcium chloride Mash pH: 5.41 Whirlpool Additions: Additions Marked Aroma were added at flameout for 15 minutes Dry Hopping Schedule: 10 grams Citra in fermenter as a pre-hop addition 3 days into fermentation dry hopped loose w/ 28g Amarillo and 50g Citra Loose in keg (w/ stainless filter over the diptube) 28g Amarillo and 50g Citra (hops remained in the keg until it kicked) Final Beer pH: 4.51 |

Download

| Download this recipe's BeerXML file |

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 45 min | 73.1 IBUs | 5.2 SRM | 1.058 | 1.017 | 5.4 % |

| Actuals | 1.06 | 1.014 | 6.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Organic 2-Row | 9.849 lbs | 67.24 |

| Malted Spelt | 3.444 lbs | 23.51 |

| Caramel/Crystal Malt - 20L | 12.54 oz | 5.35 |

| Cara-Pils/Dextrine | 7.87 oz | 3.36 |

| Acid Malt | 1.25 oz | 0.53 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Dr. Rudi | 35 g | 45 min | Boil | Pellet | 11 |

| Citra | 35 g | 15 min | Aroma | Pellet | 12 |

| El Dorado | 35 g | 15 min | Aroma | Pellet | 15.7 |

| Galaxy | 28 g | 15 min | Aroma | Pellet | 14 |

| Galaxy | 110 g | 0 min | Dry Hop | Pellet | 14 |

| Citra | 56 g | 0 min | Dry Hop | Pellet | 12 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Calcium Chloride | 5.65 g | 60 min | Mash | Water Agent |

| Calcium Chloride | 4.25 g | 60 min | Mash | Water Agent |

| Calcium Chloride | 3.70 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 2.80 g | 60 min | Mash | Water Agent |

Mash

| Step | Temperature | Time |

|---|---|---|

| Mash In | 155°F | 60 min |

Notes

| Water: .75 g/gallon gypsum & 1.0 g/gallon calcium chloride Mash pH: 5.41 Whirlpool Additions: Additions Marked Aroma were added at flameout for 15 minutes Dry Hopping Schedule: 10 grams Galaxy in fermenter as a pre-hop addition 3 days into fermentation dry hopped loose w/ 28g Citra and 50g Galaxy Loose in keg (w/ stainless filter over the diptube) 28g Citra and 50g Galaxy (hops remained in the keg until it kicked) Final Beer pH: 4.52 |

Download

| Download this recipe's BeerXML file |

RVA Manchester Amarillo/Citra Results

Wow! Not only one of my favorite hoppy beer’s I’ve brewed in awhile, but one of the better hoppy beer’s I’ve had commercially in a while! Absolutely everything I look for in a NEIPA style, incredibly soft, loads of flavor, plenty of body, and a overall smoothness that sophisticates the beer.

Despite having no Amarillo hops in the boil pot at all (boil and whirlpool) this is the predominate hop in the nose and flavor. Combining Citra with Amarillo really seems to cut down on this aggressive herbal tea and floral quality I sometimes get from Amarillo on it’s own, which helps bring it more into a fruit territory. Right away the beer reminded me of peeling back the wrapper of a fruit roll-up, I can just smell the sweetness and stickiness of those white wrappers in the hops. I’m also reminded of the aroma of the milk leftover after eating a bowl of Trix!

The longer I kept this on tap, the more I started to pickup on a vanilla richness to the in the aroma and flavor, which after using this yeast on a few more beers i’m confident this is coming from the Manchester yeast. It’s really a light vanilla wafer cookie quality. This may sound strange and out of place for a hoppy beer, but man it’s working! When I top crop this strain I get a big rich vanilla shake aroma with a touch of banana from the yeast slurry.

Great tightly packed head that sticks around nicely. I really enjoy spelt malt in these styles of beers, really seems to be beefing up the body and the higher protein should be helping with the head retention. Really enjoy pretty much everything about this beer!

London Ale III Galaxy/Citra Results

The hops are big and juicy at first pour then as the glass sits I get more of that yeast derived (I think) cracker/pepper malt character. I’m being really critical here, it’s not a huge cracker grainy character, but trying next to the RVA Manchester yeast, it’s apparent. I’ve noted this same quality int the past few hop forward beers I’ve brewed with London Ale III. It’s not a bad quality, it’s just seems to show a touch more of the grains.

The mouthfeel is great, rich and soft. I think London Ale III might have a very small edge in mouthfeel, but this was also a slightly bigger beer so I wouldn’t pay too much attention to that. In the aroma I get pink taffy, tropical notes, and sherbert. The armoa fades a bit in the glass and moves towards more of a subdued pineapple but with an earthiness quality I wouldn’t expect with these hops. Love the look of it, nice tightly packed head that sticks around, very much the same as the RVA strain. There is a slight alcohol warmth. Again, I get this yeast/crackery thing in the aftertaste that I’m fairly sure is the yeast now after using it a few times.

Overall

- Both strains have huge krausen (RVA maybe slightly bigger) that stick around forever. When it’s about time to switch to a blow off (about day 2-3 with these strains) I just open up the fermenter and scoop out about 3-5 scoops of fresh yeast sitting on top and put in a mason jar and fill with some cooled R/O water). This is a great time to add a dry hop addition as well, I have to basically dig a hole in the yeast to get the hops in contact with the beer!

- Both strains finished out about the same in terms of final gravity and final pH.

- Both strains are incredibly active, both were ready to keg after about a week. London Ale III might be tad more aggressive and quicker.

- Both strains leave a natural soft/smooth mouthfeel.

- At first I thought the RVA strain allowed the hops to shine a little more than London Ale III (London Ale III little bit of a grainy malt character vs. the light blanket of vanilla in the RVA) however after using RVA in a few more beers, I could make a case this light vanilla quality keeps the hop aroma in check a little bit. But I’m being pretty critical, they both allow for plenty of hop aroma!

- Both of these strains may well be Boddington strains, maybe harvested at different times, but to my palate (even with different dry hops) it seems obvious they are not exactly the same.

Footnotes

- H. (2010). Maximizing Hop Aroma and Flavor Through Process Variables. Technical Quarterly TQ.

- Bruce, J. (2002). Analysis of anions in beer using ion chromatography. Journal of Automated Methods & Management in Chemistry, 24(4), 127-130.

-

Verstrepen, K. J., Derdelinckx, G., Verachtert, H., & Delvaux, F. R. (2003). Yeast flocculation: What brewers should know. Appl Microbiol Biotechnol Applied Microbiology and Biotechnology, 61(3), 197-205. doi:10.1007/s00253-002-1200-8 - Boddingtons Brewery. (n.d.). Retrieved March 30, 2016, from https://en.wikipedia.org/wiki/Boddingtons_Brewery

-610x915.jpg)

Awesome post! I have a 1.045 OG session IPA fermenting with London Ale III at the moment. Can’t wait to try it.

Scott, can you go into a bit of detail regarding your dry hopping process? You mentioned you dry hop in the keg with a stainless filter over the dip tube. Can you elaborate? Do you have any issues with hop particulate in the finished beer? I have been having a hell of a time with that, which can make for a very astringent beer! Thanks!

Thanks Dan!

I use a 11 1/2″ x 2 5/8″ Corny Keg Filter 300 Micron w/ a hole drilled in for the dip tube. I also have a 21″ x 2 5/8″ one that works well too (but more expensive). Links to the filter is below. This link to a series of tweets discusses this process a little (https://twitter.com/ScottJanish/status/716755626215542784)

I slide the diptube through the hole in the filter and just dump the dry hops in loose in the keg. I then purge the keg with c02 and fill the keg (I do a closed transfer – siphon to liquid out post). I’ve never had a problem with hop particles in the beers. Maybe a few will sneak in, but after the first couple of pours I’m typically good to go.

https://utahbiodieselsupply.com/brewingfilters.php#cornydryhopper

Brilliant! Will have to pick one up!

Hey Scott, great write up and congrats. How do you go about purging your kegs? I’ve read a lot of conflicting info as to how much it takes to really purge a keg, and about co2 mixing with o2, and there is even a chart floating around showing how much is needed, and it’s s ton. I’ve considered using the full a keg with star San and push it out method, but obviously then you cannot keg hop…

I typically just add my keg hops to a keg and fill the entire keg up with C02 at about 7 PSI and purge it and let it fill (about 3 times total). I haven’t dug deep into any of the science behind the proper amount of purging, but in my experience this has worked pretty well.

Scott,

Found the discussion I was thinking of earlier – http://www.homebrewtalk.com/showthread.php?t=565834

Curious how this compares to your purging, especially based on your oxidation tweets recently.

Interesting read, thanks for sharing the homebrewtalk thread. You make a good point about the oxidation in the NEIPAs, I probably should take a closer look at my process. It seems to only be happening to my NEIPAs however, which has me confused. I haven’t had an issue with oxidation in any other style, even when I remove kegs from the keezer and leave a room temperatures for extended periods. This is why I don’t initially think it’s a process problem, but I could be wrong.

Sure thing, and I am certainly not intending on calling your process into question, merely surmising as to what in the world is going on. Your Twitter pics are crazy, I haven’t see any beer fall off that fast but I’ve never pulled any of my ne IPAs out of the fridge after kegging. There is clearly something at play in these types of beers that are ridiculously more delicate and volatile than other beers.

I have traded for trillium (I am in az) and it congress st and fort point seemed to survive the trek no worse for wear as they were delicious. So consider me confused.

Congrats on the First Place! I just judged IPAs at a local comp and there was a beer I really enjoyed that was rather hazy. I got into a little disagreement with another judge regarding the hazy as being acceptable for the style. They weren’t having it!

Brett–I think that IPA may have been mine (ended up getting HM in the mini BOS). I fermented with WY 1318 and was wondering how the haze would play with the judges. If it was mine, thanks for the good feedback!

It is unfiltered and brewed with wheat and flaked grains, but obviously it should be crystal clear like other filtered IPAs without those adjuncts. Yeast is the only possible source of haze, therefore this beer is unfinished and the brewer is an amateur. It doesn’t matter how it tastes, this beer is awful because the book published 25 years ago says cloudy IPAs are bad!

Hey Scott!

Looks brilliant. What was your fermentation temp schedule?

Why do you have Gypsum listed thrice for each recipe under “Miscs”?

Single infusion no sparge?

How many days total in primary?

Trevor

Hey Trevor – Good catch, one of those Gypsum’s was supposed to be Calcium Chloride (I made the switch) depending on your sparge and mash water volume amounts the profile is .75 g/gallon gypsum & 1.0 g/gallon calcium chloride.

These were both fermented in the low 60’s for the first 24 hours and then sat at 68F for the remainder. I believe it was only 8 days total in the fermenter.

This was a batch sparge beer, just simply empty mash tun and dumped in the treated sparge water.

Thanks!

Hi Scott. Thank you for the great write up! I’m a big fan of London Ale III for NEIPA’s so I gotta try RVA! With regards to your fermentation temps, I’ve been fermentating at 68 then raising it to 72 after 3 days (just copying a recipe I found online). Would I notice a difference with lower temps? I think I noticed some alcoholic flavor being more upfront, maybe I’m fermenting too high. Any advice would be greatly appreciated!

For high ABV beers, I’ll often ferment on the cooler side for the first few days (66-67F), then ramp it up after it starts to slow down to hopefully keep fusel alcohols lower.

noob question but why are the calcium chloride and gypsum additions split up into two parts but the “use” and “time” seem to be the same? Also you brew with 100% RO water right? Would I need to adjust the Acid Malt amount if I used 100% RO water too?

Good Questions! I do use RO water, I should have made that clearer in the post. The chloride and gypsum additions are split up for treating both the water used for the mash and the water used for the sparge separately. If you are using RO water too, I would think the same recipe, including the little bit of acid malt, would get you into the about the same mash pH range (5.4ish).

Scott do you think wlp038 might be the same as rva132?

I haven’t brewed with it, but it does seem logical that it’s at least very similar. The description (especially the the “good for top-cropping”) is pretty similar to what I experience. I don’t necessary get a dry finish with the RVA strain, but that could be more of a result of the higher mash temperatures I tend to use. If you give it a try, I’m curious of your results!

Excellent write up. After you add the second dose of dry hops loose in the keg, do you leave the keg at room temp for any amount of time or hook up to the kegerator immediately? Also, I purchased one of these dry hop filters at your recommendation and am curious if you trimmed your dip tube or just left as is.

Hope you like the filter! I did have to cut my the diptube on the kegs where I use the filter otherwise it pushes up against the bottom of the filter enough where the diptube wont seat properly. It’s really simple to cut the dip tube with a small tube cutter (http://www.harborfreight.com/1-8-eighth-inch-to-1-1-8-eighth-inch-tubing-cutter-92878.html).

I do like to leave the keg at room temperature for about a day (or at least over night), which should speed up the extraction a little.

Well the dip tube set just fine without cutting it and I’ve already racked the beer and added the dry hops so I won’t be messing with it now. I just thought maybe the hop sludge forming a cake on the bottom of the keg would pull through if the dip tube wasn’t cut, but I guess I’ll find out soon and cut it if need be. Thanks for the quick reply!

Well it’s working great! Hasn’t pulled anything through at all. Now I need like 3 more for my other kegs 🙂 One other question, I’m curious how long you typically condition your NE IPA’s. The post says you kegged in a week, but I don’t see any other notes regarding how much longer until the tasting notes. Thanks again.

Glad it worked! I have 3 of them and will likely get more! I usually let them sit about about 5 days (couple days to chill and carbonate, and another few days to settle out a little). But, I’ve had times where I needed the beer for an event and started pouring it right when it fully carbonated. Doesn’t hurt to pull a few early to test!

Hi Scott , nice write Up…

I have a question in regard of your malt…

Why did you go with spelt malt instead of wheat ? any specific reason..

I have never tried Slept .. that’s why I’m cuorious..

regard and thanks for your awasome work!

Tavo

I started experimenting with spelt in flaked form originally and like the result, so that’s what got me interested in the malted form. It generally has a slightly higher protein content than malted wheat and I’ve been told it’s “less wheaty.” Maybe a slight nutty flavor from it, however, in these high hopped beers, I couldn’t honestly say I can tell the difference between spelt/wheat. I’m hoping it helps with the mouthfeel and head retention.

Scott have you noticed a leap in bitterness post dry hopping with 1318? I recently brewed a session pale that had almost no bitterness pretty dry hop and after 4 weeks in the keg it is still too aggressively bitter. I need to start calculating Ibu contribution from dry hopping. Personally it seems this strain causes the oils to stay in suspension which essentially causes the bitterness. Thoughts?

You can see an increase in IBUs from dry hopping in these NEIPAs if your starting IBU (prior to dry hopping) is relatively low. One study found that in a beer with a starting IBU of 8.6 and dry hopped with 142 grams of Centennial (translated the figures to a 5 gallon homebrew batch) they saw a increase in IBUs from dry hopping of 18.5!

Love reading your analyses! I also use the Big Mouth Bubblers but I am curious what you are using for an airlock in the picture at the top. Or is that a plug? If a plug, do you plug the fermentor when you add your first charge of dry hops? I just tried a process where I transferred to a keg at day 4 with 5oz of dry hops and attached a spunding valve. I crash cooled this same keg at day 7 and poured some off yesterday (day 9) to find the bitterness to be too sharp despite a calculated 60 IBUs in a 1.064 OG beer w/ 200:100ppm CaCl2:gypsum. I’m thinking too much hops in the keg!

That’s a silicone ventilating water less airlock (size 10). I got them from Keystone Homebrew Supply – http://www.keystonehomebrew.com/shop/silicone-ventilating-bung-10-dry-airlock.html

I wouldn’t completely plug a plastic fermenter, just because they aren’t made to handle any pressure that builds up, but your process dry hopping in a keg with a spunding valve is a great option, transferring off the primary yeast by day four may be a little too quick. Maybe the beer will settle out a little more and the bitterness bite will fade as more hop debris drops and stays out of your pours.

Gotcha. So you don’t do anything to trap the dry hop aromas inside the fermentor after adding your first charge at day 3? I transferred at day 4 because I wanted to get the dry hops involved while fermentation was still kicking. I suppose I could try day 5 next time, although it still finished at 1.015 which is about what I was expecting.

Hey Scott,

Great article,

I was wondering if you noticed any kind of clarity changes over time with this experiment? Knowing the size of the batch, I can only assume it was around a very short time, but would you say you noticed any kind of clarity as the batch got older? Never brewed this style using spelt before and have had trouble in the past with keeping the haziness around for extended periods of time.

Thanks!

In my experience they don’t clear up, even with extended time cold in a keg. I wrote a post on haze in the style you can check out: http://scottjanish.com/researching-new-england-ipa-neipa-haze/ (Although this one cleared up, but that was intentional).

Basically, malted wheat or spelt (probably around 20%) over unmalted and dry hop early (24 hours into fermentation or so).

Do you have any idea on how you’ll dry hop/harvest yeast at Sapwood? I ask because I own a brewery in florida and with London Ale III being such a top cropper, its sometimes difficult dropping it out of the cone and getting a nice slurry for repitching, especially when dry hopping during fermentation and it all being mixed together. And with a tiny little dry hop port at the top of the fermenter, it doesnt easily lend itself to top cropping. The hops definitely get mixed in and we get some great results, but harvesting has been a challenge. Was wondering if you’ve given that any thought. Thanks and enjoy reading your stuff. Very much looking forward to the book. Cheers.