Oxidized alpha acids called humulinones are found on hops and are extremely soluble in beer. Because humulinones are approximately 66% as bitter as iso-alpha-acids, they can potentially increase a beer’s bitterness during dry hopping.

What Are Humulinones

The three alpha acids in hops that contribute to a beer’s bitterness are cohumulone, humulone, and adhumulone which isomerize when boiled into the major contributors of beer’s bitter taste. Specifically, these three acids isomerize into six iso alpha acids which are trans-isocohumulone, trans-isohumulone, trans-isoadhumulone, cis-isocohumulone, cis-isohumulone, and cis-isoadhumulone.1 However, hops also contain small amounts of oxidized alpha-acids known as humulinones (as well as oxidized beta-acids known as hulupones) which form via spontaneous peroxidation of the alpha acids and may also play a role in shaping beer bitterness.2 In fact, humulinones are one of the most abundant oxidized hop acids in aged hops.3

Humulinones are similar in molecular structure to iso-alpha-acids, but they have an extra hydroxyl group that makes them more polar than iso-alpha-acids.4 If something is more polar this means it is more water soluble, or in this case more soluble in beer. So it’s actually easier to get humulinones into beer than alpha acids.

Humulinones in Literature

Our first hint as to why any of this matters goes all the way back to 1955 when humulinones were described as being “bitter.”5 A follow-up study in 1965 described humuliones as a substance in hops which are not alpha-acids but which have bittering power and is present in beer in small amounts that will have a “marginal effect on flavor.” When introduced to beer (through hops), the study continues, it gives a “harsh lingering bitterness.”6 For brewing purposes, the first study to put an actual figure to the bittering potential of humuliones came in 1964, when it was found that humuliones are 35% as bitter as iso-alpha-acids (although this figure is later studied and increased).7 So over 50 years ago it was already established there was a measured bittering potential of humulinones which is found on hops in a form of oxidized alpha-acids. Although there wasn’t always complete agreement that humuliones was actually present in beer originally, some took the position that studying humulinoes is “purely academic since humulinone is hardly bitter and does not occur in beer or in hops,” which was clearly later found untrue, but still interesting to see how beer science evolves!8

An interesting study in 1957 looked specifically at adding humulinone directly to beers at various stages (not in hop form) and compared this to adding isohumulone directly to beers. The results also showed a lowering bittering potential of humulinone in comparison. As well as shed some light on how much humulinone is needed in beers to achieve different taste results (summarized results in chart below).9

| Humulinone | Iso-Humulone | |

| Taste Perception | ||

| Sweet | 27 | 15 |

| Normal | 30 | 27 |

| Harsh | 40 | 30 |

|

In final beer measured in mg. per kg. *1 mg. per kg is equivalent to 1 ppm |

||

Humulinone Concentration in Hops

So how much humulinones are actually in hops? Baled hops contain less humulinone then pelletized hops, about 0.3% for baled to approximately 0.5% or more with pellets. While it doesn’t seem clear yet exactly why pellet hops contain more humulinones, there is an idea that because only about 10-20% of the lupulin glands are broken when baling hops this is in stark contrast to pelletized hops where 100% of the lupulin glands are broken, which may enhance the oxidation of the alpha-acids. The low overall concentration levels of humulinones will contribute very little to a beer’s bitterness when hops are utilized in the boil or whirlpool, but when added as dry hops is where we start to see why all of this matters!10

Because of the high water solubility of humulinones described above, when dry-hopping at relatively high rates nearly all of the humulinone will dissolve into the beer. Specifically, the Maye study mentioned above found that beers that are dry hopped at .5 to 2+ lbs/barrel, which is equivalent to 35 grams to 142 grams on the homebrew scale, will see high concentrations of humulinones in the final beer. On the other hand, beers that are solely kettle hopped contain little humulinone (less than 2ppm). To show the potential of humulinone concentration from dry hopping the Maye study looked 29 commercial IPAs and found they contained anywhere from 3 to 24 ppm!

Although I previously mentioned that humulinones were 35% as bitter as iso-alpha-acids, it was later determined that they are actually closer to 66% as bitter as iso-alpha-acids.11 So 1 ppm of humulinone would equal .66 IBUs. So you can see why it’s important to look closer at the dry hopping and the potential for increased IBUs when we know how soluble they are in beer!

The Maye study also suggests that the bitterness from the humulinones is likely “smoother” because they are more polar than iso-alpha-acids suggesting that humulinones should not “stick or linger on the tongue as long as iso-alpha-acids.” So not only are humulinones slightly less bitter in terms of IBUs, it seems their role in the bitterness is less intense.

An Oregon State University study using humulinone extracts dosed into unhopped lager beer at 28 mg/L and 21 mg/L and evaluated by a panel of 10 trained tasters found that humulinone bitterness was “lower in peak bitterness, and less medicinal, and shorter in duration” compared to beers dosed with hulupones.12 Although compared directly to hulupones (and not iso-alpha-acids), it does shed a little more light on the delicate bittering nature of humulinones.

Testing Humulinone Bitterness

Although it appears easy to conclude that dry hopping leads to a pretty sizeable increase in IBUs through humulinones, this wasn’t necessarily always the case when tested. Looking more closely at the Maye study that I found fascinating, an experiment was performed with a low IBU beer (8.6 IBU) and high IBU beer (48 IBU) and dry hopped with centennial pellets for 5 days at rates of 0, 0.5, 1.0, and 2.0 lbs/bbbl. They found that the lower the dosage rate of hops the higher the utilization of humulinone with the 0.5 lbs/bll. beer had nearly 98% of the humulinone dissolved into both the low and high IBU beer! Where the highest dry hop dosage was still in the upper 80’s for both beers.

Amazingly in the high IBU beer, as the humulinone in the beer increased the iso-alpha-acid content actually decreased (at 2.0 lbs/bll there was a 38% reduction in iso-alpha-acids). So in the high IBU case, although the beer had increased IBUs from the humulinones the reduction in iso-alpha-acids basically canceled it out. Now, in the low IBU beer this wasn’t the case. Here they found as the humulinones increased from the dry hopping, the reduction in iso-alpha-acids was much smaller with only a 13% reduction in the 2.0 lbs/bll beer. So translating this to a homebrew 5 gallon batch terminology, when the low 8.6 IBU beer was dry hopped with 142 grams of centennial there was a net increase in IBUs of 18.5 IBUs!

I couldn’t find a precise reason why there was a decrease in iso-alpha-acids when the high IBU beer was dry hopped, thus increasing the humulinone content. However, it has been noted that the presence of hop particles in the boil apparently promoted the removal of iso-alpha-acids during wort cooling.13 Now, this is of course a completely different thing (boil vs. dry hopping), but maybe it’s possible the hop particles themselves in the dry hop have the potential to strip iso-alpha-acids in the higher IBU beer simply because there is more available for them to strip (just a thought).

Dry Hopping and pH

There’s more than just humulinones that can have an impact on bitterness perception when it comes to dry hopping to keep in mind. The same Maye study found in all of their dry hopping experiments there was an increase in pH as the dry hops increased. Specifically, they saw a pH rise of about 0.14 pH units per pound of hop pellets used. So again in homebrew terms if you dry hop with 142 grams (about 5 ounces) you might see an increase in pH of 0.28. This is important because a it has been found that beers with the same iso-alpha-acid content actually tasted more bitter as the pH increased.14

Hop Storage Index & Humulinone Content

The Maye study also found a relationship between the humulinone concentration of hops and the hop storage index (HSI). The hop storage index is a used to estimate the losses of alpha and beta acids during aging. Specifically, the HSI is determined from the ultraviolet absorbance measured in the spectophotometric analysis of hops.15 Essentially, this is the measurement of the deterioration of hop bitter acids. Maye found that the higher the HSI the more humulinone content a hop had. This would seem to make sense that as the HSI increases in hops (less stable varieties) there is an increase in oxidized alpha acids, which we now know is what humulinones are.

My first thought after reading the information on HSI and humulinone concentration was, what if you aged the hops a little on purpose to increase the HSI content. However, the storage times would be long and conditions needed would be too detrimental to the hop to achieve a significant rise in HSI. It was found on one hop variety that when kept in a cold place under anaerobic conditions had little change in HSI. However, storage under the most adverse conditions tested (air access, temperature +20C) resulted in HSI increase of 0.13–0.19 after 6 months; after 1 year, the total HSI values increased 0.69–1.22.16 However, It doesn’t seem to take much time at all for humulinones to form on fresh hops. For example, in just 14 days fresh Galena hops (stored under vacuum and cold) the Maye study found had a concentration of 0.47% w/w humulinones!

Below is a list of hops listed by HSI. The closer to the top of the list (higher HSI or less stable hop), the higher the likely humulinone content and dry hop bittering potential.

Hops Varities by Hop Storage Index (HSI)17

Brewing a Beer Based on the Information

I find the academic literature in brewing fascinating, but I also like to try to take the great work done the authors and try to put the data into practice on the homebrew scale. For this post I did exactly this, I decided to try to brew a hop forward beer and see if I could create bitterness with humulinones through dry hopping! After brewing, I shipped a sample of the beer to a lab to get the IBUs tested. It is my understanding of the studies that spectrophotometric IBU test, which is what the lab used on my beer, will in fact detect an IBU increase from the humulinones. However, it would take a HPLC analysis to measure the iso-alpha-acids and humulinones concentrations separately.

I went with a sessionable hoppy beer recipe with plenty of oats, which I found has many possible benefits in a previous post looking at the brewing literature. I learned I needed to keep the IBU total low in order to try to get a bitterness benefit from the dry hopping, so I went with 10 IBUs. Because I still wanted a strong hop flavor in this beer, I decided to get all the IBUs from a post boil 90 minute steep hop addition. A recent 2010 study, which I’ll likely dissect a little more closely in a future post, found that beer’s brewed with “longer postboil residence of kettle hop additions led to more hop flavor and aroma” concluding that “longer postboil residence, approaching 90 min, is far better than times shorter than 60 min.”18 So because my total hop in the boil pot was so low (only 16 grams in a 5 gallon batch!), I decided this might be the best way to get my biggest hop flavor punch from the small addition.

Because the literature suggested that increased humulinone concentration in beer is required than iso-alpha-acids to achieve “normal” bittering, suggesting that lower concentrations might even come across as “sweet”, I decided to use a couple hop varieties I thought might take advantage of this sweet/lower bittered hoppy beer. Cluster, one of the oldest U.S. varieties grown in the U.S. and not often looked at as a for dry hopping, but on it’s own I find the descriptions very intriguing (strawberry, creamy, and apricot).19

Combining Cluster with Mandarina Bavaria, which has said to have strawberry and pineapple characteristics, I was hoping the two would combine for an interesting sweet fruit aroma for this creamy oat and chloride heavy low ABV base!20

Recipe Details

| Batch Size | Boil Time | IBU | Hop Stand | SRM | Mash pH | Beer pH | Original Gravity | Final Gravity | ABV |

| 5.5 gal | 45 min | 10.1 IBUs | 90 Minutes | 3.0 SRM | 5.51 | 4.45 | 1.049 | 1.013 | 4.70% |

Water Profile

| Gypsum (S04) | Calcium Chloride (CaCl2) | S04:CaCI2 Ratio |

| 74.7 ppm | 163.4 ppm | 0.46:1 |

Fermentables

| Amt | Name | % |

| 7 lbs | Organic Brewers Malt (Briess) (1.8 SRM) | 56.00% |

| 4 lbs | Oats, Flaked (1.0 SRM) | 32.00% |

| 1 lbs 8.0 oz | Malted Spelt (BESTMALZ) (2.4 SRM) | 12.00% |

Mash

| Step | Temperature | Time |

| Mash In | 152°F | 60 min |

Hops in Boil/Whirlpool

| Amt | Name | %/IBU |

| 16.00 g | Citra Steep/Whirlpool 90.0 min | 10.1 IBUs |

Dry Hops

| Amt | Name |

| 84.00 g | Cluster – See Notes for Specifics |

| 84.00 g | Mandarina Bavaria – See Notes for Specifics |

Misc

| Amt | Name | Type |

| 1.00 tsp | Irish Moss (Boil 15.0 mins) | Fining |

| 0.50 tsp | Yeast Nutrient (Boil 15.0 mins) | Other |

Yeast

| Lab | Yeast Name |

| RVA | Manchester Ale (Boddington) |

Brewing Notes

- Fermentation was at a constant 68F

- Day 2 of fermentation – Top cropped yeast for further use and dry hopped with 56g Mandarina Bavaria and 28g Cluster (putting the higher total oil hop in the fermenter w/ active fermentation in hopes of more remaining in final beer).

- Day 9 of fermentation – Kegged with 56g Cluster and 28g Mandarina Bavaria (left at room temperature for 24 hours then put in keezer). Hops remained in keg until it kicked.

IBU Lab Test Results

The Maye study tested the bittering of humulinones up to 2 lbs/barrel in dry hops (approx 142 grams), so I decided to go even higher and dry hopped with 168 grams (6 ounces) in a 5 gallon batch. I don’t know what the HSI of Mandarina Bavaria is, but in the list above I can see that Cluster’s HSI is 16, which means it likely bittering potential from humulinones is lower than most hops.

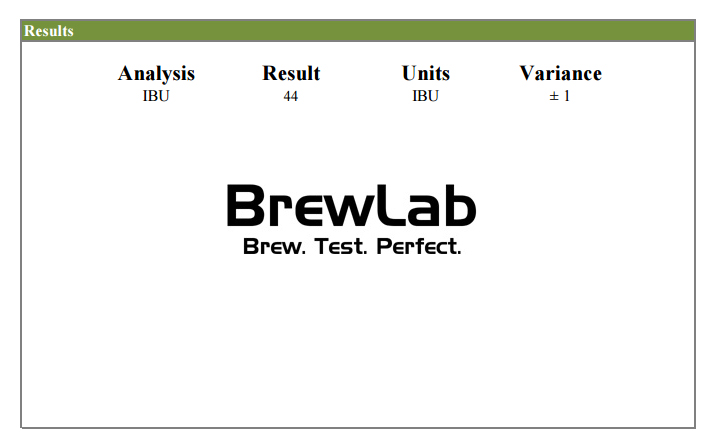

As you can see from the lab test below, this particular beer did see a fairly drastic increase in estimated IBUs from the dry hops of over 33 IBUs, which it seems likely is in part from the increase in humulinones. However, because humulinones are less bitter than iso-alpha-acids, it should taste less bitter than the 44 IBU figure implies. This is even more interesting when considering if I would have used a higher HSI hop like Columbus or Cascade the IBU number could of even been higher.

I find this incredibly interesting, not only can you get a substantial amount of bitterness from dry hops (when the initial beer’s IBU levels are low), you can also get a smoother less intense bitterness via the humulinone concentration. It’s also interesting to learn based on this post that it’s likely this beer’s final pH increased by more than 0.28 units from the heavy dry hop addition.

| Estimated IBUs | Tested IBUs | Est. Increase In Part from Humulinones |

| 10.1 | 44 | +33.9 |

Tasting Notes

For an experiment beer, I really like how this turned out! The hop combination is definitely different than more traditional American IPA hop builds, as its much sweeter with a jam like condensed fruit aroma. Apricot and strawberries and red raspberries come to mind. The aroma reminds me a little of the jelly filling in donuts or even the apricot flavored syrup you can get at Perkins. For such a small hop steep addition, I definitely still get hop flavor in this beer. The mouthfeel is soft as expected with this yeast strain, oats, and chloride. At a DC Homebrewer’s meeting a few even thought it was a lactose IPA, along the lines of Milkshake IPA from Tired Hands, which I can totally see how you’d get this impression with a combination of the sweet fruit jam like aroma with a touch of vanilla that this yeast strains seems to produce and the creamy oat NEIPA style mouthfeel. It taste dryer than the final gravity would suggest. Great head on first pour, but dissipates fairly quickly (30% oats is a likely the culprit).

As far as the bitterness, it’s got a smooth low supporting bitterness. You can tell it’s a lower bittered beer, but I’d be surprised if you told me it only had 16 grams of hops total in the boil! Although it may just be in my head from the research, the bitterness does seem apparent and first but disappears quickly after swallowing, which would agree with the smoother less lingering bitterness from the humulinones. I had multiple people try this beer without them knowing anything about it and only one said the bitterness seemed low. Although I didn’t really know how this would turn out, for a low ABV session beer like this, the IBUs of 44 with help from the dry hops seem about right for an easy drinking flavorful beer. I’m wondering if this approach to bittereing isn’t boosting the perceived hop flavor a little. To me it seems higher IBU more aggressive bittered beers seem to hide the flavor a little (no data to back this up however).

Final Thoughts

- Humulinones are found in greater amounts on pellets than leaf hops and seem to also be linked closely to a hops storage index (HSI).

- Humulinones are about 66% as bitter as iso-alpha-acids (1 ppm of humulinone would equal .66 IBUs).

- Humulinones are more polar than iso-alpha-acids, which means they more soluble in beer.

- Humulinones may give a beer a smoother less intense bitterness.

- Humulinones seem to only increase a beer’s IBU total if the original beer was low in IBUs as well.

- Dry hopping raises the pH about 0.14 pH units per pound of hop pellets used and the higher pH actually increases the bitterness perception in beers.

Footnotes

- Intelmann, D.; Batram, C,;Kuhn, Ch.;Haseleu, G.;Meyerhof, M.;Hofmann, T. Three TAS2R bitter taste receptors mediate the psychophysical responses to bitter compounds of hops (Humulus lupulus L.) and beer. Chem. Percept. 2009

- P. H., M. Q., & T. S. (2012, August 7). Brewery Scale Dry Hopping: Aroma, Hop Acids, and Polyphenols. Retrieved from http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/34093/Wolfe_thesis.pdf

- Dusek, M., Olsovksa, J., Krofta, K., Jurkova, M., and Mikyska, A. Qualitative determination of Beta-acids and their transformation production in beer and hop using HR/AM-LC-MS/MS. J. Agric. Food Chem. 2014

-

Preparation of Dicyclohexylamine Humulinones and Dicyclohexylamine Hulupones. (2016). Journal of the American Society of Brewing Chemists ASBC. doi:10.1094/asbcj-2016-1127-01

- Cook, A. H., Howard G.A., and Slater, C.A. The chemistry of hop constituents VIII. Oxidation of humulone and cohumulone. J. Inst. Brew. 1955

-

Hudson, J. R. (1965). The Rationalization Of Hop Utilization-A Review. Journal of the Institute of Brewing, 71(6), 482-489. doi:10.1002/j.2050-0416.1965.tb02076.x

- Whitear, A.L., and Hudson, J.R. Hop resins and beer flavor III: Hop resins in beer J. Inst. Brew. 1964

- Verzele, M. (1986). 100 Years Of Hop Chemistry And Its Relevance To Brewing. Journal of the Institute of Brewing, 92(1), 32-48. doi:10.1002/j.2050-0416.1986.tb04372.x

-

Howard, G. A., & Slater, C. A. (1957). Utilization Of Humulone And Cohumulone In Brewing. Journal of the Institute of Brewing, 63(6), 478-482. doi:10.1002/j.2050-0416.1957.tb06287.x

- Humulinone Formation in Hops and Hop Pellets and Its Implications for Dry Hopped Beers. (2016). Technical Quarterly TQ. doi:10.1094/tq-53-1-0227-01

- Algazzali, V., and Shellhammer, T. Bitterness intensity of oxidized hop acids: Humulinones and hulupones. J. Am. Soc. Brew. Chem. 2016

- Peltz, M., Algazzali, V., & Shellhammer, T. (2016). Sensory bitterness quality of oxidized hop acids: Humulinones and hulupones [Abstract].

-

Applications of High-Performance Liquid Chromatography in the Control of Beer Bitterness. (1986). Journal of the American Society of Brewing Chemists ASBCJ, 44. doi:10.1094/asbcj-44-0101

- Meilgaard, M., and Trolle, B. The utilization of hops in the brewhouse. Proc. 6th Congr. Eur. Brew. Conve., Copenhagane. 1957

- Hop Storage Index. (1979). Journal of the American Society of Brewing Chemists ASBCJ, 37. doi:10.1094/asbcj-37-0184

- Mikyška, A., & Krofta, K. (2012). Assessment of changes in hop resins and polyphenols during long-term storage. J. Inst. Brew. Journal of the Institute of Brewing, 118(3), 269-279. doi:10.1002/jib.40

Smith, B. (n.d.). BeerSmith (Version 2.2). Retrieved from http://beersmith.com/order/

H. (2010). Maximizing Hop Aroma and Flavor Through Process Variables. Technical Quarterly TQ. doi:10.1094/tq-47-2-0623-01- Barth, S. (2011). The hop aroma compendium: A flavour guide. Nürnberg: Carl.

Barth, S. (2012). The hop aroma compendium: A flavour guide. Nürnberg: Carl.

-610x915.jpg)

http://www.baywa.eu/fileadmin/media/relaunch/Downloads/.DE/Ackerbau/Hop_Sales_Article_Kaltner.pdf

You do an excellent job with these articles, I really enjoy reading them. For this experiment I wonder how many IBUs this beer would have tested without the dry hop addition? I am not sure what IBU extrapolation formula you used, but I would guess it was not fit using 90 minute hop stands.

Thanks! I wish I would have sent in a sample to be tested prior to dry hopping, something I thought about after I dry hopped. I used BeerSmith’s IBU estimation for Citra with a 90 minute hopstand. I didn’t hold a constant temperature, rather at flameout I cut the heat and let it cool naturally for 90 minutes. However, I did send in a beer that BeerSmith estimated to have 70 IBUs and that came back at less than 40!

Really interesting work.

Could you repeat the experiment without using any hop stand hops. As has been mentioned, I wouldn’t trust guesstimates of what hop stand hops contribute and so it would be good to have that eliminated from the IBU figure.

I would be very grateful if you could email me if you get some more results as I messed up two brews last autumn with excessive bitterness from dry hopping.

Great article and a lot of ideas to ponder after reading. It sounds like this may provide a good use for some of my older stored hops (I have some 3-4 year old crop hops vacuum packed and in the freezer) rather than use them in the kettle.

Since they have been stored well (vacuum packed and froze), it’s unlikely the level of humulinones potential of the hops increased much based on the research. Only if they are extremely poorly stored would you see this. It’s still probably best to go off of the HSI for potential bittering from humulinones. If you are brewing beers with hopstands/whirlpools, it might make sense to use these older hops during this process since the hop oil compensation is so drastically altered during fermentation anyways.

Great article! This validates data I see when dry hopping sours: I get a pH raise of 0.1-0.2, or around there. As far as the 90 minute hop stand, at what temperature do you add the hops, and what temperature is the wort after the 90 minutes? Do you feel that the Technical Quarterly article is supported by your experience doing such an extended hop stand?

Thanks,

Dan aka the MTF Wiki Man

Hey Dan, big fan of MTF Wiki!! In this beer I added the hops at flameout (so at 212F) and after 90 minutes the beer was down to about 190-195F. I just tried this process again in two more hop forward beers to see if I can tell a difference with a much bigger hop steep (this beer was only 16 grams). I’m anxious to see how they turn out. As far as the paper goes, they didn’t put any science behind why the longer hopstand was beneficial, this was just found from their tasting panels. In this beer, I was surprised however at how much hop flavor I was getting from such a small hop addition in the kettle. In general though, I’ve been skeptical of big whirlpool additions, I just don’t see how useful it is to load up your kettle with hop oils and then let fermentation scrub most of them out (although the biotransformation of some of the oils seems beneficial). I think it’s worth experimenting more with the process of a low IBU beer being heavily dry hopped to take advantage of the bittering from humulinones, which is supposed to be less intense, which makes me wonder if I’m not picking up more hop flavor (or perceiving more hop flavor) in part from the less intense bitterness.

Hey how did those 2 beers turn out with the bigger hop additions?

Cheers

Lukasz

Great article. I’ve been scratching my head as to why whenever I’ve dry hopped heavily with a certain batch of Centennial pellets the beer has ended up being incredibly bitter/ashy/dry…I had a hunch they were oxidised and your research seems to back that up. I just need to formulate an easy test before dry hopping (smell test, dry hop bud lite…?)… BTW also had the exact same happen with a batch of amarillo.

Heard about this on the Experimental Brewing Podcast, so had to check it out. What a great read.

I have scratched my head many a time wondering how my dry hopped low IBU session pales turn out bitter!

One thing I notice is that dry hopped beers increase in bitterness over a time period of around 2 weeks after kegging. I always presumed that this was just an increase in percieved bitterness due to the aroma and flavour dropping out. Any thoughts on this?

Thanks for the message! Are you keeping your kegs cold over the 2-weeks? Perhaps your getting a slightly slower extraction from the hops at the lower temperatures. Although I remember a study that suggested full extraction cold should still only take 3 days to get extraction (32F).

See http://www.sciencedirect.com/science/article/pii/S0963996916302046

Interesting, thanks for sharing! This could also be playing a role. “At low bitterness, beers with hop aroma added were perceived as more bitter, and of ‘rounded’ bitterness character relative to those without hop aroma.” Perhaps the keg hops are increasing the hop aroma character to a point that’s also increasing the perceived bitterness.

I had an IPA recently that turned from a light fruity bitterness to a punch in the face lingering bitterness through keg hopping only took a couple days before the results came through, not 2 weeks.

It was really interesting, the beer went from clean and fruity, almost tropical fruit juice to a beer with a strong and lingering bitterness with a nice thick mouthfeel that melted into a buttery aftertaste (23% oats ty Scott).

Keg hopped with a large dose of Galaxy, Chinook, Columbus and Nugget. Like… Went to town on that keg.

It sounds like you’re on the right track here! Try with a 20IBU beer to achieve the same thing here, this will increase the lingered bitterness while still producing a sessionable, moderate bitterness IPA.

Overall, A+ read

Loved this article Scott, very informative. However, I’d love to know how you calculated your dry hop bitterness with this beer.

Cheers.

I used BeerSmith for the estimated IBUs and sent the beer to the BrewLab for actual testing, which resulted in 44 IBUs.

Thanks for doing all of this research Scott, very interesting. What was the alpha acid content in your citra hops? I’m a little skeptical as to the 10.1 IBU calculation pre-dryhop, as it seem that the IBU’s drawn from the hops during whirlpool are difficult to calculate exactly, especially if the hops were added right at flameout. By my calculations, if you didn’t chill the wort quickly, you could have had up to 21 IBU’s drawn from the citra hops (at 11% AA), if it took an hour to drop below 185f. Still, that leaves 23 IBU’s unaccounted for, and some of that it seems could be from your intense dry hopping regimen. Thoughts?

I’m not sure what the exact alpha acids were for that Citra crop, I just used BeerSmith data for Citra and their method for calculating whirlpool/steep hop additions. Your probably right that their calculation aren’t going to be exactly right, but like you said, still surprising to see such a high IBU when so little hops were used on the hot side, which I think the literature was pretty convincing that a portion of the increase was likely due to the intense dry hop combined with a low starting IBU.

Hello great research. I have a doubt. Do you think it can be applied for a dry hopped berliner weisse, it is a small beer in ABV content, but in the other side it is low in PH. do you think it can increase de IBU like that, I asking because I planing to brew a hopped sour. So maybe a heavy dry hop can make the job thanks.

That’s a good question, I don’t know if the lower pH would affect the solubility of humulinones, but I would guess you would still get them in the beer. So as long as the starting beer was low in IBUs (which I assume it is because you used lacto) then I do think you’d increase the bitterness perception by dry hopping the beer. The increased aroma of the beer may also increase the bitterness perception. We do know that dry hopping will slightly increase the pH of your beer, so it could make it a touch less tart, which is something to keep in mind.

You do an amazing job ! A huge thanks from France !! 😉

I hop that (pun intended :P) you continue with this amazing job of putting science back to the homebrew level !

(PS : it’s so sad that so many french homebrewer don’t understand english, we do not have experts like you that write good french brewing blogs here ;( )

A friend made a low-gravity tart Saison (lightly Lacto-soured, 3.9% ABV) with no boil hops – just a 170F whirlpool hopstand, and dry-hopping. It came out with substantial bitterness, estimated by a professional taster as 30+ IBU, even though technically there would be almost no isomerized alpha acids.

Seems the sensation of bitterness is much greater for low-gravity and low-alpha beers (even though this one had a substantial mouthfeel), possibly accounting for why people often report getting no bitterness from dry-hopping a typical IPA. If the beer has a substantial malt flavor and substantial IBU already, the dryhop addition probably doesn’t add any perceived bitterness; but with low malt and low iso-alpha, the hop oils are perceived on the palate much more strongly.

I recently brewed an improvised ale with Voss kveik and, despite an adequate grain bill, seemed very thin to me. I was fretting about grains when I realized that the real problem was lack of assertive bitterness. After being discouraged from trying a boiled hop tea, I took a chance and dropped 2oz if Bru-1 pellets in there. It’s only early in day 2, but I could swear it was more bitter! Searched and found this article and now I know why, thanks!