After doing the research for a post on the potential benefits of brewing with oats, I decided to put the research to practice and brew a beer with 40% raw steel cut oat groats. Because oats have the potential to reduce the fermentability of wort, I went with a hoppy session beer. I used 6-row as the base in hopes of thinning the mash (to compensate for the viscosity the oats will impart) as well as the added benefit of increased enzymes (although not necessary). 6-row malt also has a slightly higher protein percentage than 2-row, which I hope will help with the head retention that can suffer as a result of the higher oat percentage. I used all New Zealand Rakau hops in the boil, which are higher in low cohumulone as a percentage of acids, which might also help with the head retention.

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 45 min | 77.0 IBUs | 3.5 SRM | 1.054 | 1.017 | 4.8 % |

| Actuals | 1.05 | 1.016 | 4.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (6 Row) US | 8 lbs | 58.06 |

| Organic Steel Cut Oat Groats | 5.5 lbs | 39.91 |

| Acidulated (Weyermann) | 4.48 oz | 2.03 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Rakau (Alpharoma) | 50 g | 45 min | Boil | Pellet | 10.5 |

| Rakau (Alpharoma) | 50 g | 5 min | Boil | Pellet | 10.5 |

| Citra | 10 g | 7 days | Dry Hop | Pellet | 12 |

| Citra | 56 g | 0 min | Dry Hop | Pellet | 12 |

| Galaxy | 56 g | 0 min | Dry Hop | Pellet | 14 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Calcium Chloride | 11.90 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 4.80 g | 60 min | Mash | Water Agent |

| Irish Moss | 1.00 tsp | 15 min | Boil | Fining |

| Yeast Nutrient | 0.50 tsp | 15 min | Boil | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Manchester Ale (Boddingtons) (132) | RVA | 73% | 65°F - 72°F |

Mash

| Step | Temperature | Time |

|---|---|---|

| Saccharification | 157°F | 120 min |

Notes

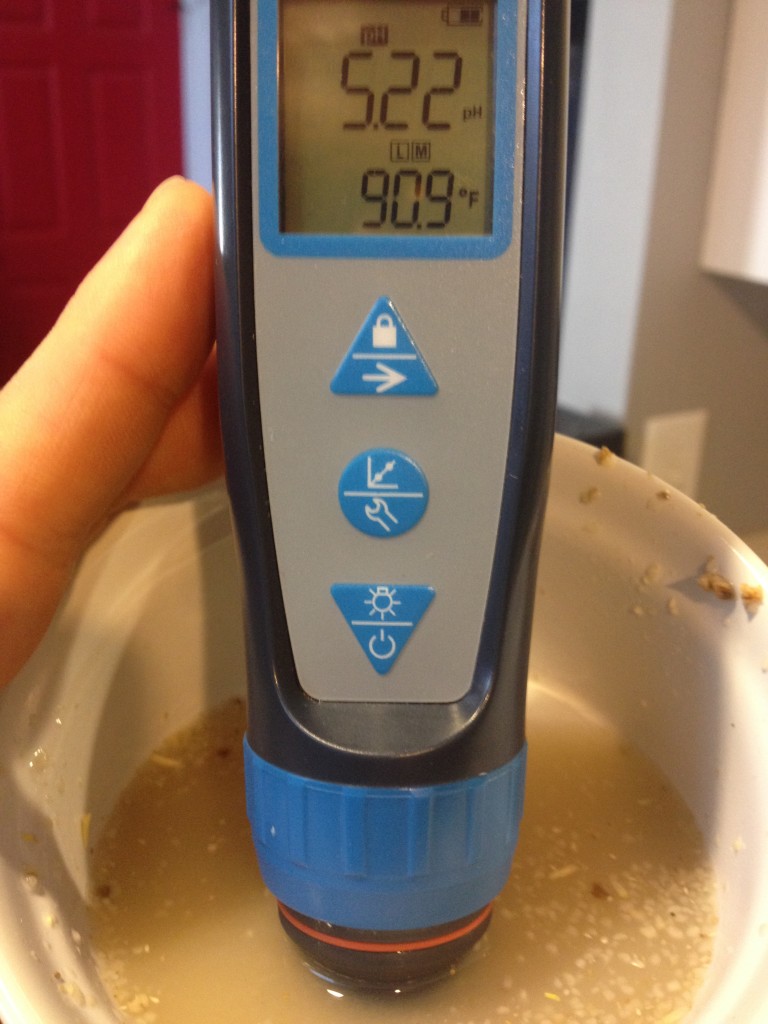

| Fermentation Temperature: 69F Water Profile: 100% R/O treated with .5 g/gallon gyspum and 1.25 g/gallon calcium chloride 74.7ppm Sulfate and 163.4ppm Chloride Mash pH 40 minutes in: 5.22 Dry Hopping: 10grams of Citra was added to the fermenter as a pre-hop addition. 3 days into fermentation 28grams Citra and 28grams Galaxy were added loose to primary. 28 additional grams of both Citra and Galaxy were also added to the keg and left in until keg kicks. No Whirlpool hops. |

Download

| Download this recipe's BeerXML file |

Result

I ran the wort into the boil pot slowly to try to prevent a stuck sparge, which I surprisingly had little trouble with despite 40% oats (6-row may have helped with this). It took 2 hours to reach full conversion when adding the raw milled oat groats directly to the mash (without doing a cereal mash). Because I did a no-sparge (all the water added to the mash at once) I wonder if the conversion was slowed by a dilution of the enzymes. The research suggested that the mash pH would be lower with the increased volume of oats, but I didn’t see this, I had a mash pH of 5.22 40 minutes into the mash that dropped to 5.1 at 90 minutes. I probably could have back off the acidulated malt a tad. I saved and froze (in mason jars) some of the leftover wort from this mash to use as yeast starters for the future based on the research suggesting oats are beneficial for yeast health.

The research suggested that oats might reduce the lag time by having faster yeast growth, I don’t have a way to actual measure this, but fermentation did appear to begin quickly. Less than 15 hours post-pitch I checked on the ferment and it was already visible fermenting (picture below) which means it was likely going hours before I looked. Three days into fermentation when I added the dry hops (which I had to dig a hole into the yeast to do), I also top cropped a mason jar of the yeast, it was either that or move to a blow-off.

Freshly top cropped Boddington yeast. It was either that or switch to a blow off! pic.twitter.com/KXMQbeIGMZ

— Scott Janish (@ScottJanish) March 20, 2016

15 Hours Post Pitch

Just 9 days post brewday I’m already enjoying this beer. It’s definitely cloudy, as expected with the big addition of oats as well as the Boddington yeast strain and dry hops.

Head retention is OK considering the healthy addition of oats. Below is a picture about 3 minutes post pour, you can see it’s trying to hang around. After awhile it does dissipate to a really thin layer. I think the 6-row might have helped the foam a bit considering I’ve used flaked oats in smaller amounts and had less retention than this beer is getting (it could be improved however). With a mash of 157F and 40% oats, I did see a drop in fermentability. The final gravity of 1.016 is just about right in my opinion for a session IPA like this.

Overall, it’s a pretty damn good low ABV beer. The mouthfeel is incredibly smooth! The oats, yeast strain, and chloride seem to be combining nicely here. Aroma out of the glass is of mellow fruits like strawberries and peaches with a little bit of citrus character (orange lifesavers come to mind). I’ve been a little disappointed in this particular pound of Citra I purchased and used in this beer, but even still, there is a decent aroma in this beer. At just 4.5%, this beer does have a good deal of flavor! Some malted spelt/wheat or carapils might be a good addition to help give this extremely smooth mouthfeel some more depth. I purposely left whirlpool hops out of this beer and added a small 10 gram charge of Citra pre-ferment to see how this would affect the perceived hop flavor of the beer. The hop oils removed during fermentation seem to be so great that huge whirlpool hops are becoming more questionable to me. This beer is only increasing my skepticism, there is definitely a hop flavor that follows the aroma in here. Perhaps the hop flavor would have been intensified with some whirlpool hops, but at the very least it seems that whirlpool additions can be cut back a little in hop forward beers and shifted more towards the dry hop.

-610x915.jpg)

What an excellent series of posts from initial study of the scientific literature to your application of your findings. What is your source for the raw oat groats? Lastly, is there anyway to effectively clear this type of beer, for those that may drink with their eyes? Again, great site Scott, thank you!

Thanks for the compliment! You could always use a fining agent like gelatin to try to get this beer a little less cloudy, which is resulting from oats as well as the dry hopping and yeast strain. However, if yeast cells can strip hop oils as they flocculate, it also seems logical to conclude gelatin would strip the oils as well!

Could you explain your whirlpool theory? You think it doesn’t have as big an impact on hop flavor and aroma as people say?

It’s really something I’d like to try to look into a bit more. I’m not saying whirlpool hops aren’t worth it at all, I just question if loading up the whirlpool really translates into more hop flavor and aroma. Just for myself, I’ve put as much as 6 ounces into the whirlpool and tasting this beer prior to dry hops (after fermentation) I couldn’t tell any hops were in there. After researching the dry hopping post, it was alarming to me how much of the hop oils we cram in the whirlpool are substantially reduced after fermentation. Again, it’s something I’d like to try to look into a little more, but I’m comfortable at least reducing my whirlpool additions at this point.

My process includes a whirlpool and a double dry hop routine; once while it’s still fermenting and then in the keg. I like my IPA’s on the day I keg; they are right where I want them. Hoppy; aromatic and juicy tasting. Often I question myself as to why I dry hop them in the keg…but if I don’t the aroma and flavor can diminish quickly due to things dropping out. Sometimes, I end up over hopping them.

I crave “green” beers. Some of the popular IPA’s and Double IPA’s on the market are a combination of IBU’s, hop flavor and malt flavor. A well crafted balance, but I prefer hoppy beers to be all hop flavor and aroma; true hop flavor not a representation of it.

Timing for adding hops to achieve this is delicate. A lot gets pulled out as the fermentation winds down. Trying to layer in big whirlpools, dry hops and keg hops can quickly lead to an out of balance beer or a waste of product. Gonna give this more thought.

Any reason that raw oats are used in this beer instead of flaked/malted? Would you still get the benefits mentioned in your other article with flaked/malted?

Thanks!

I wanted to try using raw oats without doing a cereal mash to see what the results would be. Many of the benefits in the article were actually studied from malted oats. But using the flaked vs. the raw oats, I don’t think you’ll notice much of a difference (in my case I did notice it took longer to get full conversion however).

Thanks for all these recipes and posts, they are very helpful to other home brewers! Do you think a 120 minute mash is necessary for any 40-50% oat malt bills? Thinking of brewing a 50% oat IPA and appreciate any info on that. Thanks.

How was the haze permanence with this recipe?