Cashmere IPA

Fermented with Conan and Hefeweizen Yeast

O

ne of my favorite things to do at the brewery is experiment with small batches. Sometimes I’ll transfer 5-gallons of fermented hoppy wort pre-dry hop to a purged keg with experimental hops. Other times I’ll take a little wort pre-ferment to test out different yeast strains or blends; we just got a small 18-gallon conical to make this type of experimentation a little easier and more representative of brewing something on the bigger tanks.

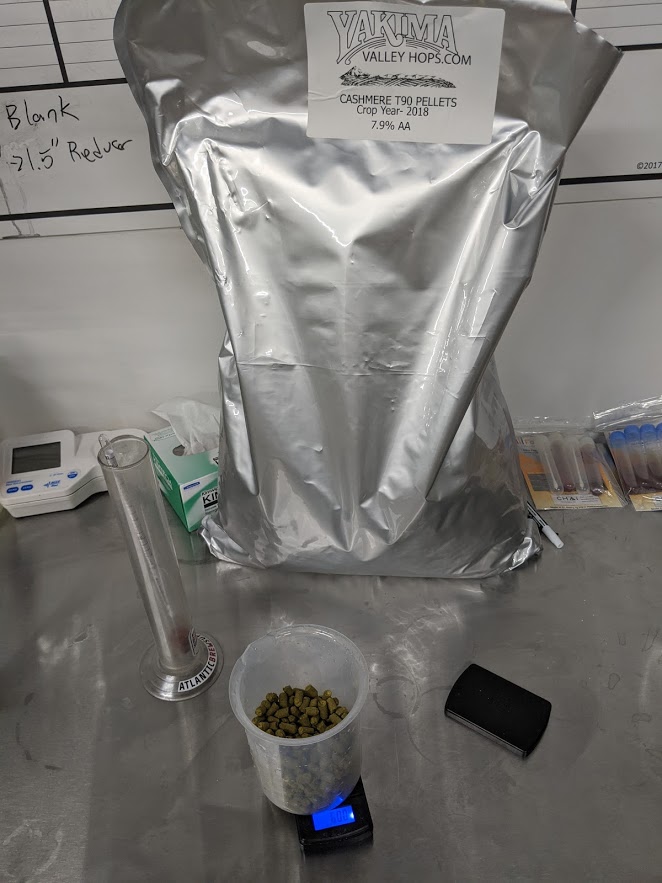

This particular experiment is a built in part on yeast blend beer that we’ve done in the past at Sapwood combining hefeweizen yeast with RVA Manchester and active fermentation dry hops with Cashmere (only this time I used a Conan strain). The slight vanilla yeast characteristic you get with RVA Manchester combined with approximately 10% hefeweizen yeast lends an approachable vanilla wafer-like beer. The active fermentation dry-hopping helps to create a baseline hop-fruit character but with most of the volatile green compounds blown off with the CO2 produced during fermentation. After drinking a beer from Tree House called Cachet (a DIPA w/ Cashmere dry hops), we were inspired to do a more grown-up version of our RVA/hefeweizen yeast blend beer. So, we upped the basemalt to get into DIPA territory (for a starting gravity anyways) and dry hopped it with 100% Cashmere at a high rate of 12 ounces per 5.5 gallons (~16 grams/liter).

I took approximately 5.5 gallons from an active fermenting 20 bbl tank (about 24 hours post-pitch) with a Conan strain and added 5 grams of WLP300 from a vial. I still want the fruity ester profile you can get with Conan, but with a banana hefe-edge while attempting to keep any clove flavors to a minimum. I fermented the mix-pitch relatively cool, starting at 65°F (18°C) and allowed it to finish off closer to 70°F (21°C). I dry hopped in two stages, the first with 6 ounces (170 grams) at the tail end of fermentation in primary and again with 6 ounces (170) grams in a purged keg (with a dip tube filter). After three days in the keg, I transferred out into a serving keg where it sat on CO2 to carbonate. Because of the intense dry-hopping rate, this beer needed close to two weeks in the serving keg to settle down. After the green hop bite died down, we had the beer on tap for a few days for us to try then eventually filled 16-ounces mini crowlers and sent 18 cans out into the world. People liked it a lot, much more than I thought they would (spoiler alert, people like sweet things!).

Recipe

Brewed: March 2020

Tasting notes: April 2020

Batch size: 5.5-gallon

| OG/FG/ABV | Est. IBU | SRM | Water | Mash Temp. |

|---|---|---|---|---|

| 1.086/1.037/6.43% | 101 | 5.0 | ~150 ppm chloride and 100 ppm sulfate |

160°F

|

| Grain | Percentage |

| 2-Row | 53% |

| Pilsner | 19% |

| Malted Naked Oats | 9% |

| Malted Wheat | 9% |

| Carafoam | 5% |

| Chit Malt | 5% |

| Hot-Side Hops | Amount | Addition |

| Simcoe | 16 grams | Mash Hop |

| Simcoe | 18 grams | First Wort |

| Mosaic | 90 grams | Whirlpool |

| Sultana | 50 grams | Whirlpool |

| Dry Hops | Amount | Day/Duration |

| Cashmere | 170 grams |

Tail end of fermentation

|

| Cashmere | 170 grams |

Purged Keg Post-fermentation

|

| Yeast | Temperature | Duration |

|---|---|---|

| JY243 – Burlington Beer Factory + WLP300 (5 grams) | 65°F (18°C) | Allowed to finish off at 70°F (21°C) |

Results

To say this beer is sweet is an understatement; it’s not rare for imperial stouts to finish this high (or much higher), but for an IPA this one is up there! Surprisingly, because of the high dry hopping and hefeweizen yeast, the result isn’t “worty,” but more of a dessert-cookie maltiness. This is in the category of a dessert IPA for sure, especially considering if you down one 16-ounce can you’re also taking down 400 calories (but who’s counting). It’s got a super soft mouthfeel, with a cloying lingering sweetness.

If you like Banana runts, then you will love this beer. Once that descriptor was used, I couldn’t shake it. It’s one big banana runt bomb! Buried in this is also faint vanilla wafer, lemon poppy-seed, melon, and coconut flavors. With just a small pitch of WLP300 (after fermentation was underway) it still has plenty of banana! I’m always amazed at how little a pitch of a different strain can drastically change the fermentation profile of a beer.

Overall, it’s a fun beer. I’m not sure we’ll ever considering scaling this up, but for 5-gallon it was fun to have on tap for a few days. I’d probably mash a little lower next time and try to get that FG a little lower, considering this is generally a good starting gravity for a DIPA. My guess is that anyone replicating this recipe will get a lower FG and if you want to bump it up, you could consider boiling maltodextrin and filtered water and jumping from keg-to-keg to build up the FG. I’m still a little unclear why it finished so high, but sometimes it’s fun to brew something unique and out of character! Runt up!

-610x915.jpg)

Treehouse definitely has hefe yeast esters in there house yeast beers and some fans have gone to great lengths to crack the davinci code yeast strain there using..any idea why your attenuation was so low ? Cleary more than mash temperature seems to be the causing this

Concerning this part “The active fermentation dry-hopping helps to create a baseline hop-fruit character but with most of the volatile green compounds blown off with the CO2 produced during fermentation.”. What you’re saying is that green, grassy compounds are removed during fermentation and fruity ones aren’t as affected? Could you provide me with more information on that? I was not able to find an explanation in your book.

Also, using Mosaic in the whirlpool – does that not get rid of all the 4MMP goodness we want? Sorry, but I am a bit confused.

Heat will remove 4MMP, so I would expect lower whirlpool temperatures would help preserve some of them. However, I’d like to see more research on whirlpool temperatures as it relates to thiol retention. Dry-Hopping is likely the best way to get 4MMP from hops into the beer.

Thank you for the reply Scott and please excuse my delay!

Yeah, that’s what I would have said as well. I am not using 4MMP hops on the hot side anymore at all, because of fearing the loss of the good stuff. Probably too overcautious here?

Also, what was your reasoning behind using Simcoe that early? As far as I remember, it also comes with a bunch of 4MMP?

Yup, it’s been our experience that some of the greener characteristics from dry-hopping will fade with active fermentation dry-hopping. There is research that suggests that these compounds (hydrocarbons like myrcene) are typically much more volatile than the fruitier and more polar monoterpene alcohols (linalool, geraniol, etc.). So, if they are more volatile then factors like heat, or in this case active fermentation, are more likely to scrub or remove these compounds and leave the more polar ones.

Very interesting! Is this purely anecdotal or have you found recent research on this (active fermentation volatility) as well?

How long did this take to finish fermentation?

I used a different grain bill but also mashed at 160F for a 1.080 OG and used WLP644. I got a super fast start of fermentation activity (~4h from inoculation), but it seems it has also gone down after 24h, and now my wireless hydrometer says it’s at 1.038 (~51% attenuated) and very slowly going down (1-2 points per day).

Did you experience something similar?

Thanks!

It took about 6 days total to ferment out. How did your beer turnout?

Why the Carafoam? I saw that you have another article mostly about Briess Carapils where you mention Carafoam briefly. In that article, you said Carafoam was like chit malt – could you elaborate? My homebrew store doesn’t carry chit, but they do have Carafoam. Is it a suitable alternative? I’m curious why you used the Carafoam in this recipe – particularly since you also have chit malt.

I’ve pretty much moved to brewing with chit malt exclusively. Mainly after reaching out to BESTMALZ®, who offers an under modified 2-row summer barley malt called chit malt and asked about carbohydrate levels. I was curious most about beta-glucans levels and was told that “the beta-glucan levels in chit malt are higher due to the lower water content and provoked growth at steeping and germination than normal barley malt.” They also assume that beta-glucan levels in chit malt are comparable to that of oats, but they haven’t tested this yet. There may also be antioxidant benefits from LTP1 proteins (which help head retention) which are reduced the more modified the malt (Carapils is described as a highly modified). So I prefer using undermodifed carafoam or chit over carapils (especially after that experiment with 50% carapils).